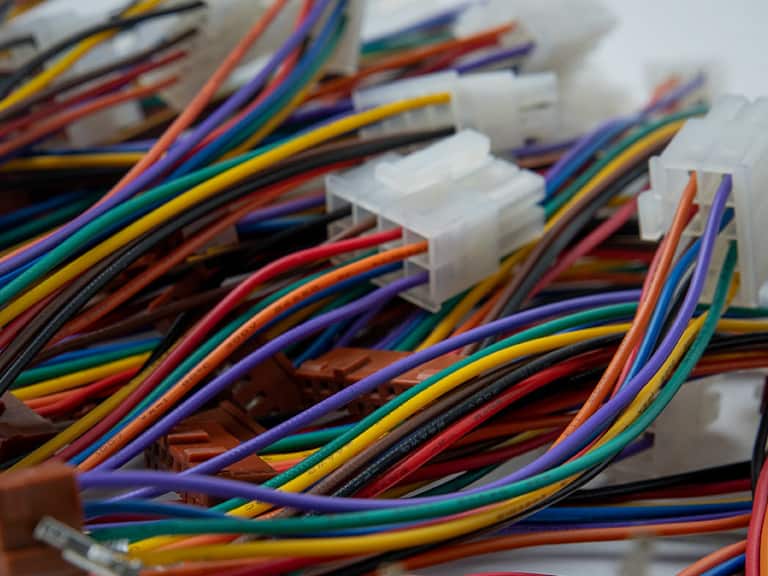

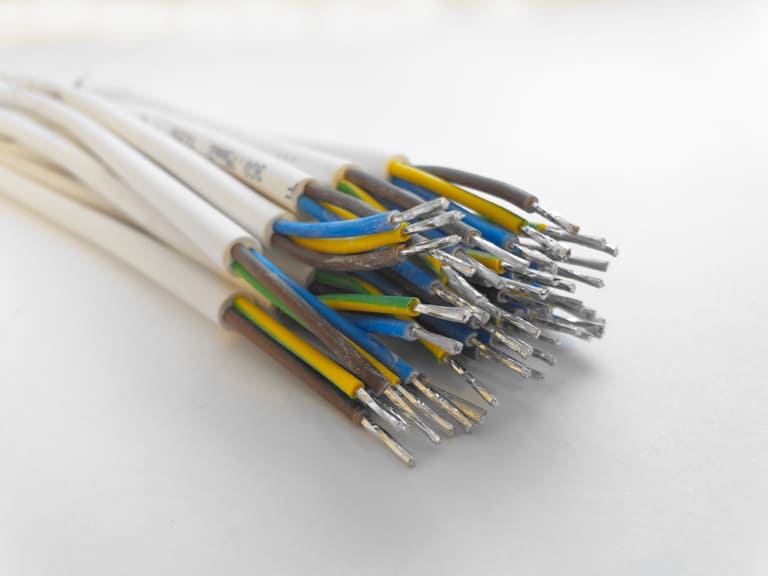

Simple cable sets and complex wiring harnesses with up to several hundred cables – we provide you with everything from one source. Thanks to our many years of experience in cable harness production, we can economically produce both small and large series.

Competence center for wiring harness production

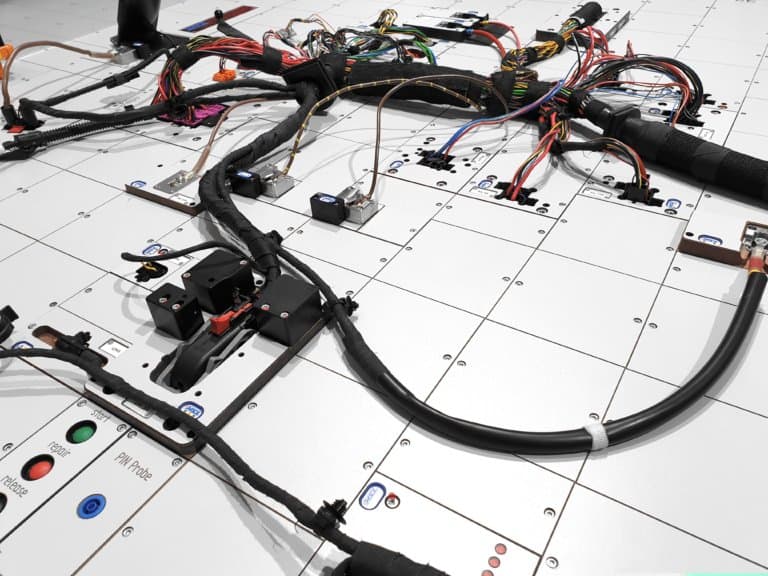

The pre-assembly of cables is mostly fully automatic, thanks to the latest machines and equipment. However, assembly on laying boards is still done manually, which is not least decisive for the price level. In order to be able to realise attractive prices nevertheless, our cable harnesses and cable sets are produced not only in Germany but also in Southern and Eastern Europe, Asia and North Africa. Depending on the requested quantity and complexity, we select the appropriate production location – your contact person will always be us in Germany.

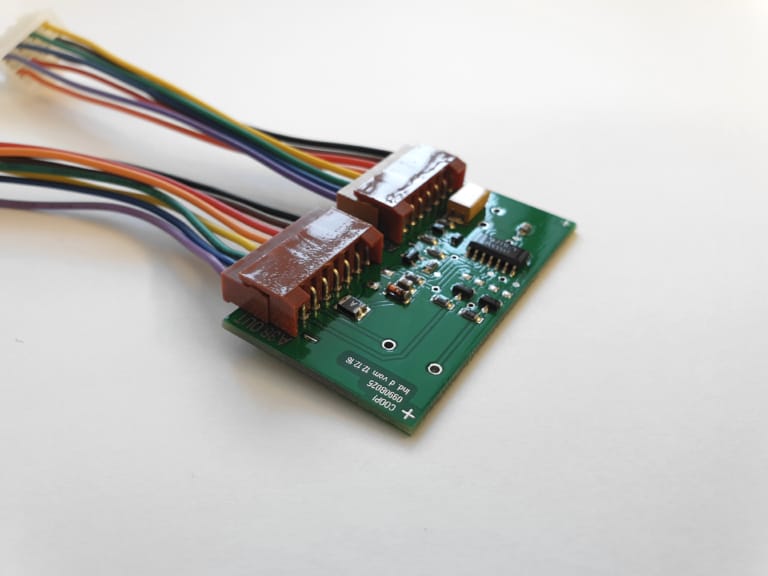

If required, we also integrate preassembled cable harnesses into complete assemblies so that our customers can obtain ready-to-install systems. The advantage of having only one contact person is obvious.

From wiring harnesses to ready-to-install systems

An essential part of our corporate philosophy has always been the endeavour not only to supply individual parts to our customers, but also to develop and manufacture ready-to-install systems and to supply them in line with their requirements. In recent years, we have also successfully dealt with the related technologies – Plastics Technology and Metal Working– in addition to cable harness production, so that today we are able to develop ready-to-install systems according to customer specifications and to produce them in series. It is always a special challenge to realize individual products even in small and medium quantities (annual requirement < 1,000 pcs.). Examples of successfully implemented projects can be found under Component Assembly.

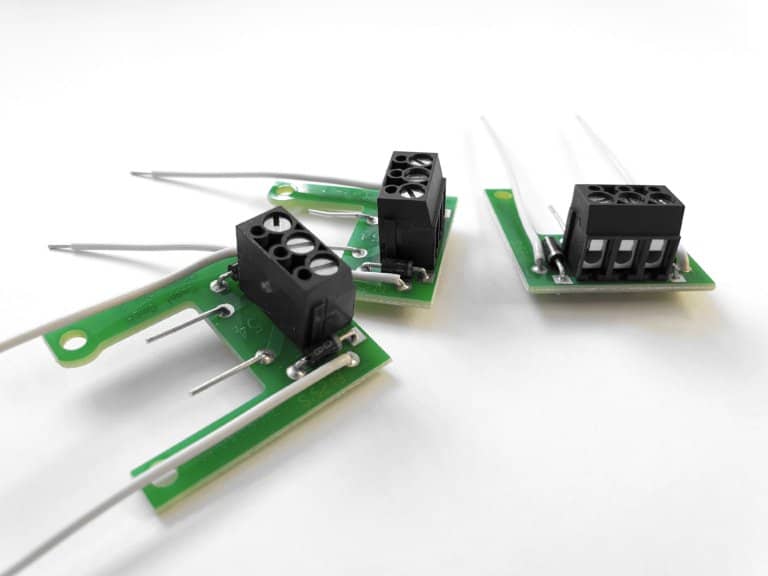

Challenges in cable assembly

Cable assembly refers to the development and production of ready-to-install cables, cable sets and cable harnesses. The following challenges, among others, arise in this process:

- Variety of variants and modularization of wiring harnesses

- Heat generation of electrical components

- Country-specific fire protection regulations

- Mechanical wear and strain relief

- Seals for cable glands

- High currents and voltages

- Ambient temperatures and media resistance

- Mountability

- Less installation space

- Bending radius

- Weight of the wiring harness

The importance of cable assembly in today’s world

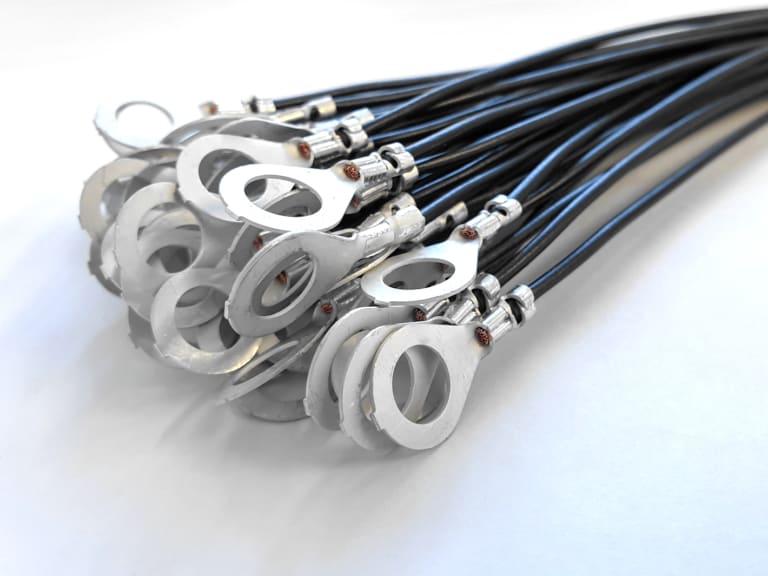

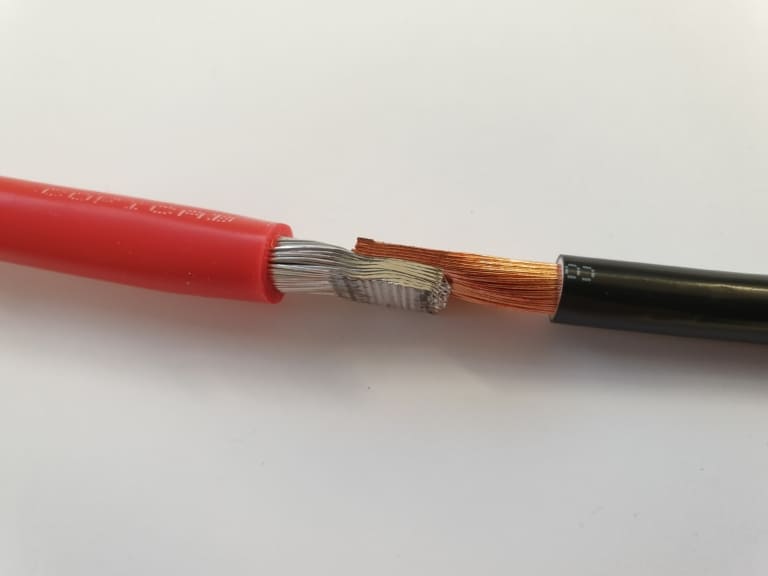

Cable assembly is an essential process in the electrical and electronics industry that ensures the performance and reliability of a wide range of products and systems. By precisely manufacturing and adapting cables and wires to specific requirements, cable assembly enables the efficient transmission of signals and energy in vehicles, machines, systems and many other applications. This specialized process includes cutting, stripping, tinning, crimping or attaching connectors as well as testing the finished components to ensure high quality and functionality.

For companies that value precision and reliability, cable assembly offers customized solutions that are precisely tailored to their individual needs. Whether for small, medium-sized or large industrial companies, the flexibility and adaptability of cable assembly enables optimal integration into existing systems and processes, resulting in increased efficiency and reduced downtime. In addition, the ability to realize specific configurations and specifications helps maximize end product performance while ensuring compliance with strict industry standards and regulations.

In today’s fast-paced and technology-driven world, the demand for quality cable assembly is greater than ever. Companies that are able to provide innovative and reliable cable harnesses and systems are at the heart of the industry, driving progress in sectors such as automotive, aerospace, medical, robotics and renewable energy technologies. By investing in advanced manufacturing technologies and a commitment to continuous improvement and quality assurance, these companies are positioning themselves as preferred partners for leading manufacturers worldwide.

For potential customers looking for a reliable partner for their cable assembly needs, it is important to select a provider that offers not only technical expertise and product quality, but also outstanding customer service and support throughout the project lifecycle. Such a commitment to excellence and customer satisfaction is a clear sign of a supplier that is willing to go beyond simply supplying products and create value for their customers and their end users.

In a world where precision, reliability and flexibility are critical, cable assembly is at the heart of technological advancement. Companies that specialize in the development and supply of high-quality cable assembly solutions are indispensable partners for industries striving for higher performance, efficiency and innovation.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.