Due to the assembly of components in job order production, we can also supply our customers with ready-to-install systems. Highest quality, delivery reliability and documented processes are a matter of course for us.

From individual part to assembled assembly

In addition to the development and production of individual parts in the areas of Cable Assembly, Plastics Technology and Metal Working, as a full-service supplier we also offer subassembly assembly in contract manufacturing.

Whether simple or complex, small series or large series – we will find a suitable solution. Starting with the development and production-optimised design of the individual parts, through component research to the first assembly of a prototype, we offer everything from one source. After approval, we set up a series production according to your requirements and deliver the ready-to-install systems to you worldwide. We would be pleased to convince you with speed and competence.

We see complex tasks as a challenge and solve them with unconventional approaches.

Development of ready-to-install assemblies

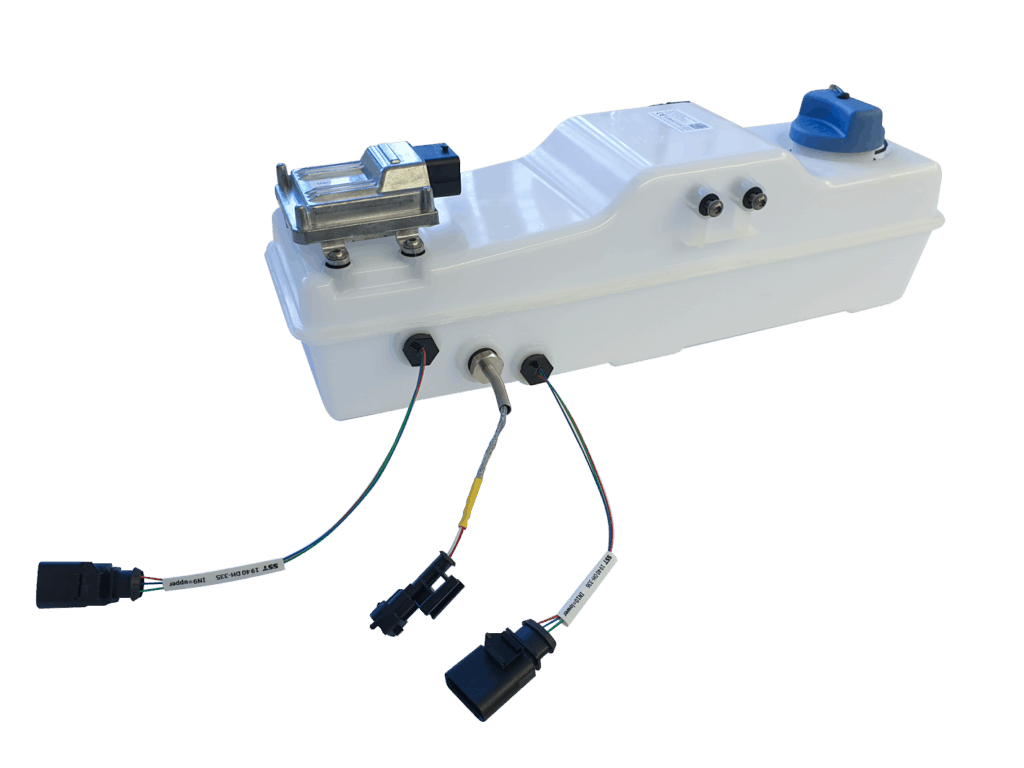

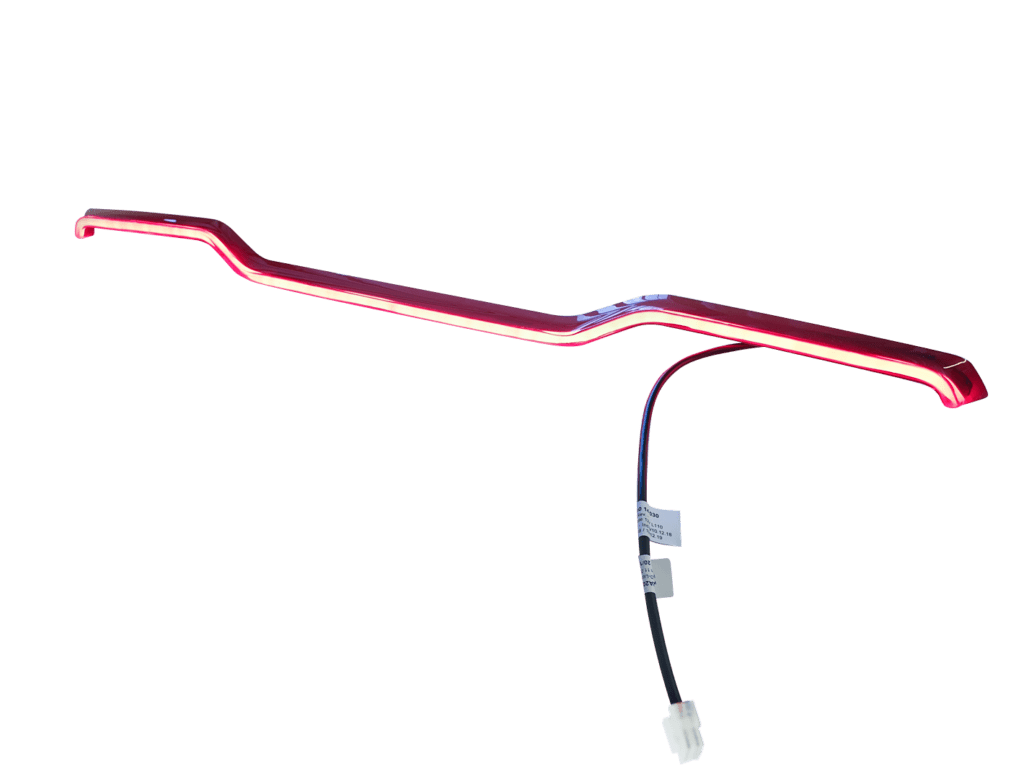

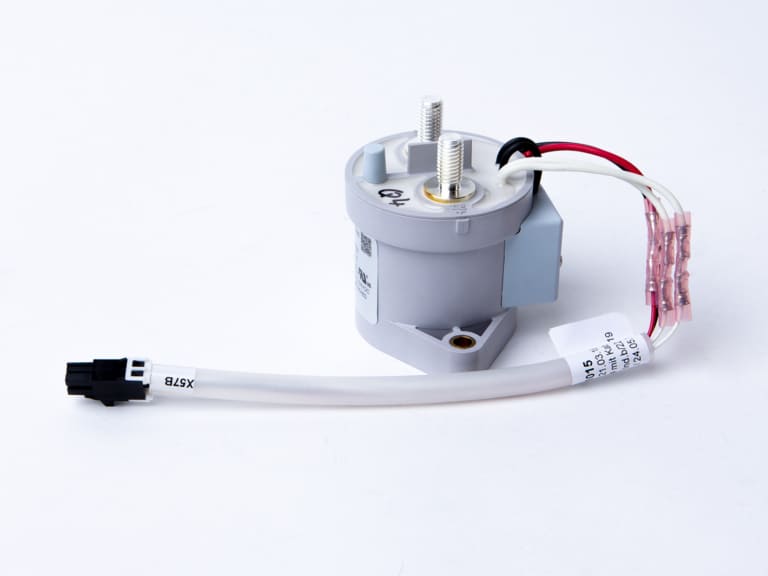

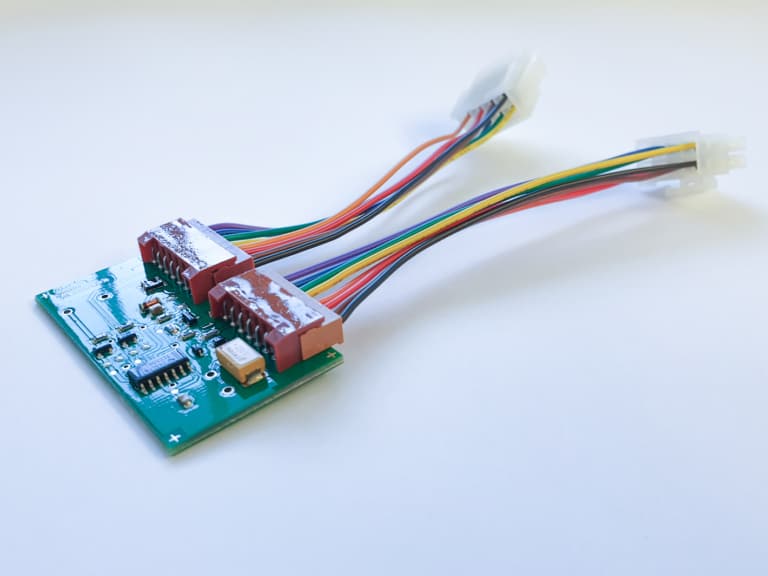

From the very beginning, an essential part of our corporate philosophy has been the endeavour not only to supply individual parts to our customers, but also to develop and manufacture ready-to-install systems and to be able to supply them in line with their requirements. In recent years, in addition to cable harness production, we have also successfully dealt with related technologies – plastics technology and metal processing – so that today we are in a position to develop ready-to-install assemblies according to customer specifications and produce them in series. It is always a special challenge to realize individual products even in small and medium quantities (annual requirement < 1,000 pcs.).

Component assembly in job order production – simple to complex

Our expertise lies primarily in the assembly of electronic components and assemblies made of plastic and metal parts. The assemblies often consist of a combination of the individual product families. Thanks to our many years of experience in the development and production of individual parts, we know exactly what needs to be taken into account to ensure consistently high quality.

- Flexible capacity planning

- Simple and complex assemblies

- Structured assembly processes

- Serial numbers

- Batch Traceability

- Fast fixturing

- Cost optimization of purchased parts

- Development of the individual parts

- Conversion of existing products

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.