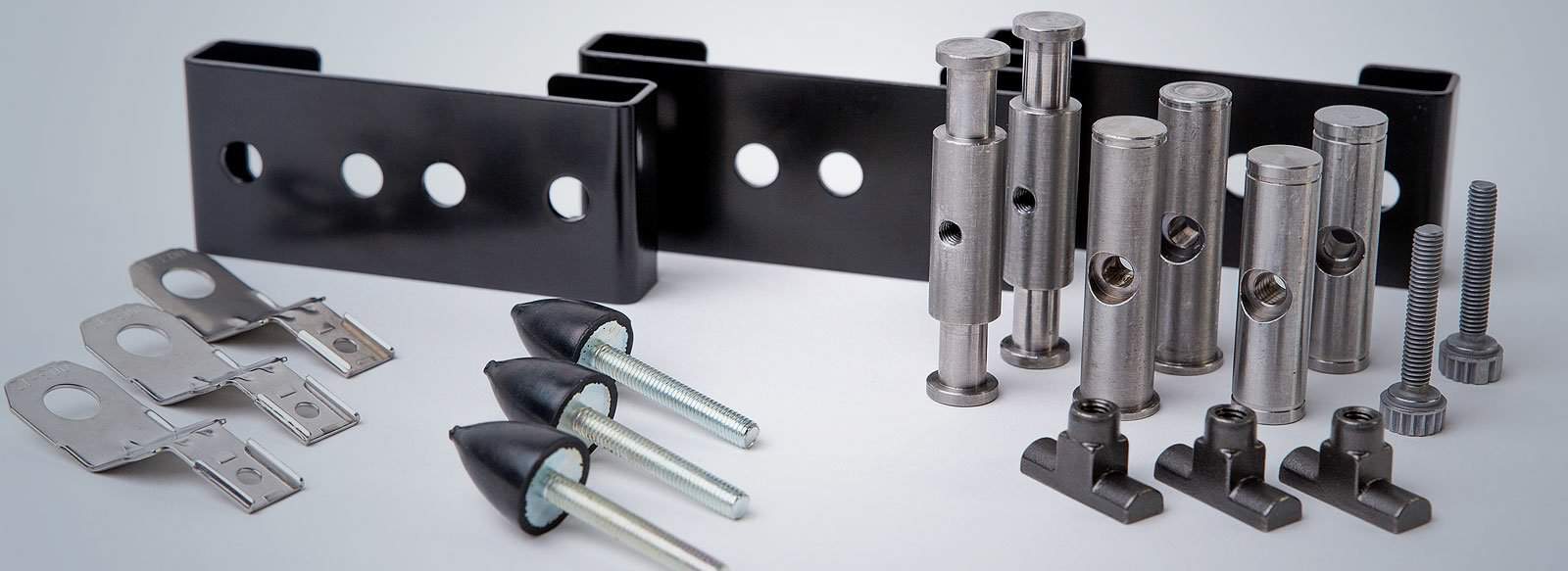

Stamping, laser cutting, bending, casting or a combination of these metal processing methods: Tell us your requirements and we will supply you with a finished component – for small and large series. We will be pleased to submit you a non-binding offer.

Precise machining of metal parts

Our expertise lies in the development and production of simple to complex, high-precision components made of steel, stainless steel, aluminium, brass and copper. Send us your drawing or CAD data and do the test. We will be pleased to submit you a non-binding offer.

Services

Development of metal parts

As an independent development partner and series supplier, we always aim to develop the best and at the same time most economical solution for our customers from a technical perspective.

According to customer specifications, we develop suitable solutions and compare different materials, manufacturing processes, supply chains, the administrative effort and potential risks. As a result you will receive a selection of different options with a recommendation. All you then have to do is select.

Available materials

We manufacture metal parts according to drawings and CAD according to your requirements. If required, we also support our customers constructively in the design of components and the selection of materials. Overengineering is easy, but finding a material that is sufficient for the application is not. Here we try to choose a material with an excellent price-performance ratio.

- Steel & stainless steels

- Brass

- Copper

- Aluminium

- Titanium

- Special alloys

- POM, PE

- Cast steel

- Grey cast iron

- and many more

Metalworking – What we can do

Stamped parts

Depending on the required quantity and component geometry, punching is carried out with single tools, multi tools or progressive tools. We select the most economical variant to suit your requirements.

Modern laser cutting

Laser cutting is particularly suitable for small or medium quantities. Further advantages are a short delivery time and low to no investment costs, since no expensive tools and devices have to be manufactured. In each individual case we weigh up for our customers whether punching or laser cutting is more economical.

Precise bent parts

The production of metal bending parts is carried out manually on the bending bench or with the help of hydraulic presses and bending prisms. Larger series can be produced cost-effectively with progressive compound tools.

Simple and complex milled parts

The production of precise milled parts is carried out economically and effectively on 3- or 5-axis milling machines. Besides turning, drilling and grinding, it is one of the most important machining techniques.

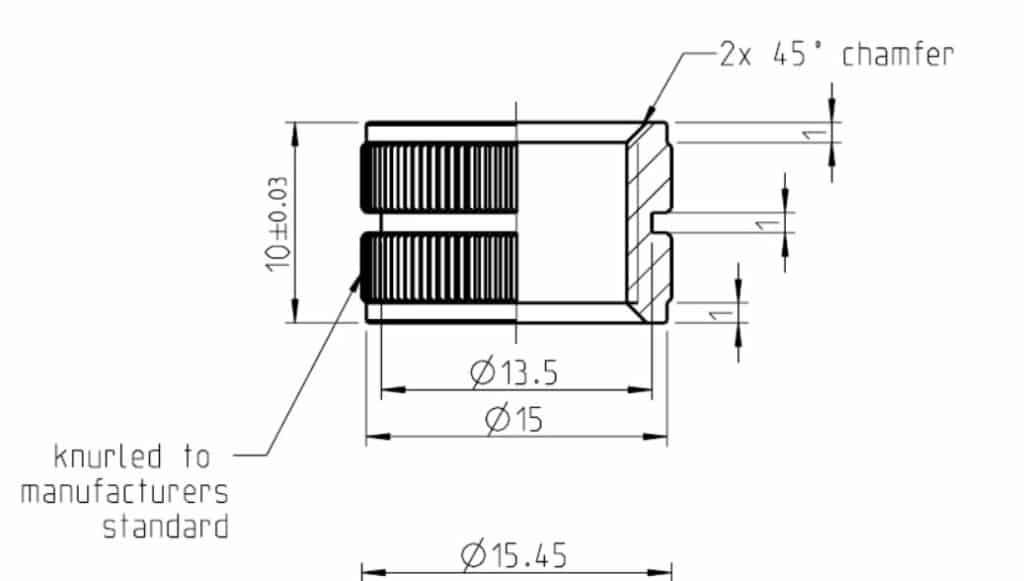

Precise turned parts

The production of rotationally symmetrical components is carried out cost-effectively on lathes and CNC turning machines. Besides milling, drilling and grinding, it is one of the most important machining techniques.

High quality castings

Depending on the quantity, requirements and component complexity, we select the appropriate casting process. If required, the castings can be meticulously examined in the laboratory, including preparation of a test certificate.

Finishing

After component manufacture, we provide a suitable finish: anodising, powder coating, painting, blasting, burnishing, nitriding, nickel-plating, galvanising, chrome-plating etc.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.