3D printing is now a firmly established part of modern development and series production. It has been used in a wide range of industries for over 10 years and the technology is developing rapidly, especially in terms of material selection. New materials are constantly being introduced that better and better imitate the material properties of classic plastics in terms of strength, ageing resistance, appearance, elasticity and tolerances. The latest printers can now even print color gradients, material composites and elastic components with surprising precision.

3D printing shortens our development times

We use our 3D printers mainly for customer-specific developments, but we also offer our B2B customers contract manufacturing. This allows us to significantly shorten the development phase and carry out functional tests “overnight” with near-series parts. We also use our 3D printers to produce fixtures and test setups for our component assembly.

Materials for 3D printing

We can print high-strength and impact-resistant materials as well as soft, elastic materials with properties comparable to silicone and EPDM. Depending on the application, we are happy to advise our customers and suggest a suitable material.

Special materials

- Impact-resistant, high-strength materials (PU resins)

- Heat-resistant materials (up to approx. 238 °C)

- Self-extinguishing and halogen-free materials in accordance with UL-94-0

- ESD dissipative material

- Transparent materials

- Elastic materials with 40, 50 and 80 ShA

- Ceramic-like materials

- Biocompatible materials

- Particularly economical materials for rapid feasibility studies

3D printing process: SLA and FDM in comparison

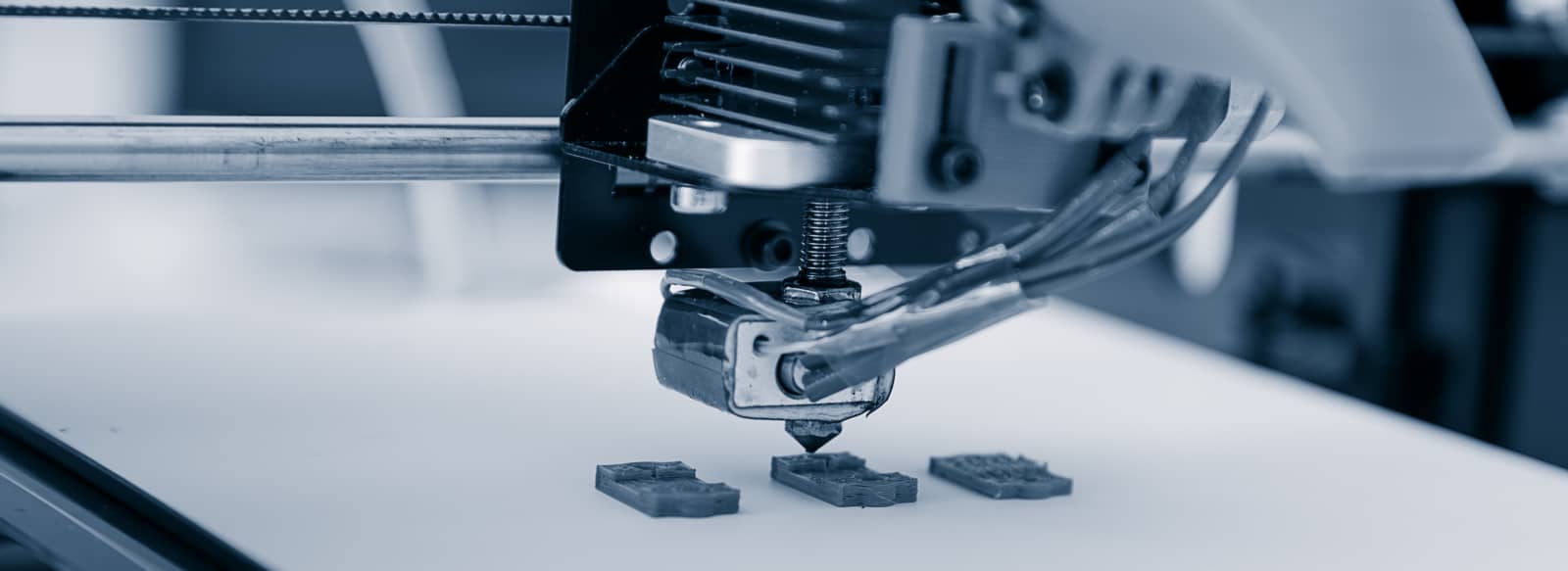

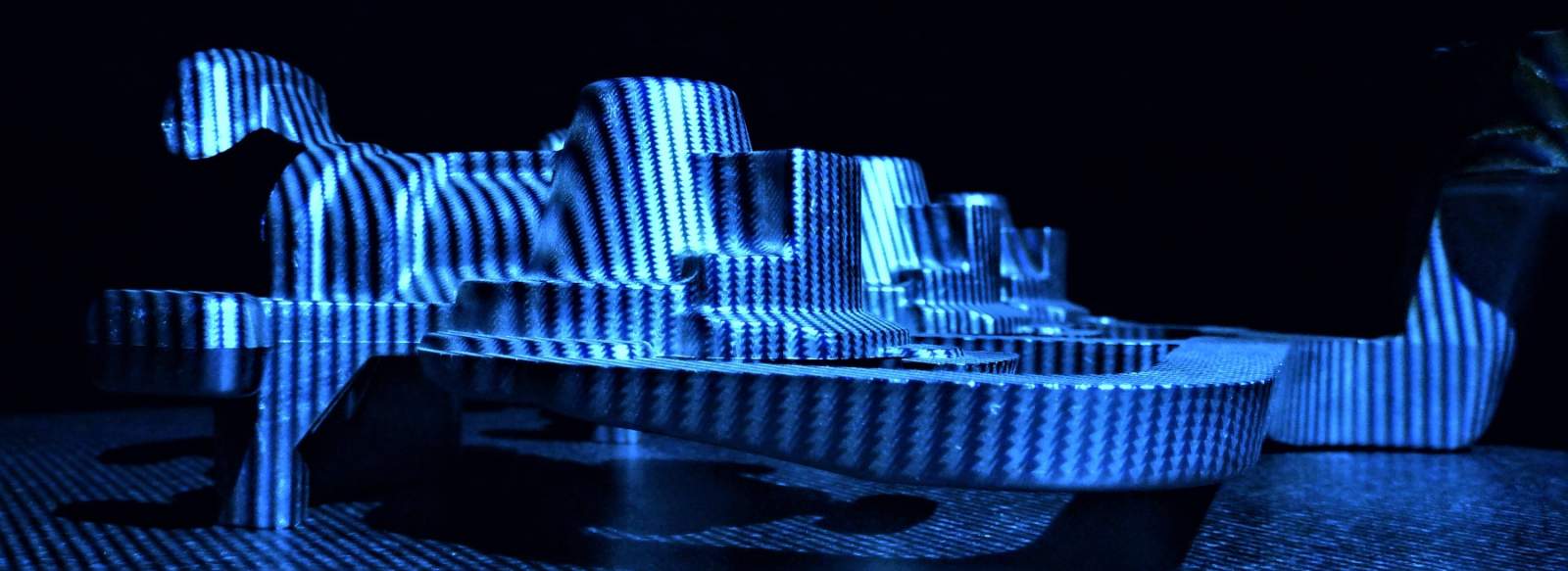

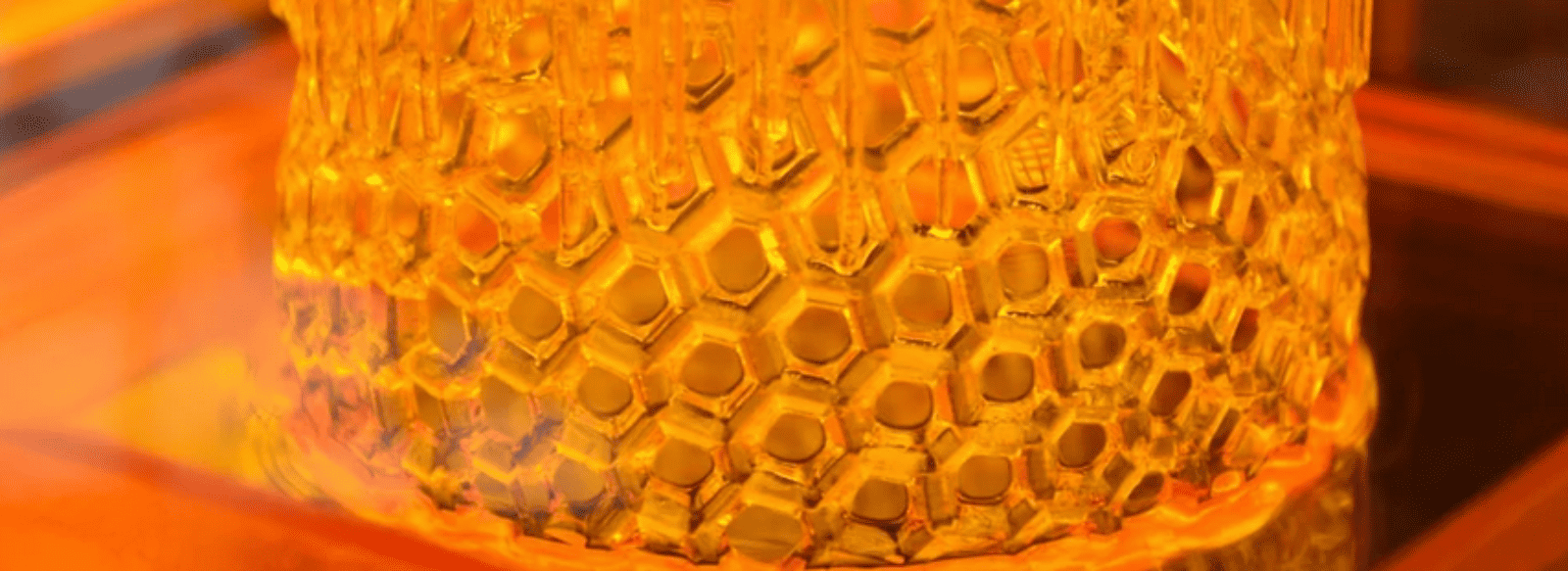

If high precision and surface quality are required, SLA printers (stereolithography), which produce components from a liquid resin bed, are particularly suitable. This makes it possible to produce components that come very close to injection molded parts in terms of appearance and function. However, resins are at a disadvantage compared to FDM (Fused Deposition Modeling) printers in terms of ageing resistance, at least that was the case until recently. FDM printers extrude fine, thermoplastic filaments, which are positioned in rows via an extruder head. There are now new materials (polyurethane synthetic resins) with increased ageing resistance for SLA printers, which can be used to produce high-performance components for machinery, automotive or aerospace applications, among others.

We can produce components using both printing processes and will be happy to advise you free of charge.

“As an engineering office, we are passionate about developing new products or optimizing existing components together with our customers. To do this, we have access to a wide range of state-of-the-art analysis equipment, making us fast, reliable and, above all, independent of external laboratories.”

– Thomas Goldhofer, CEO

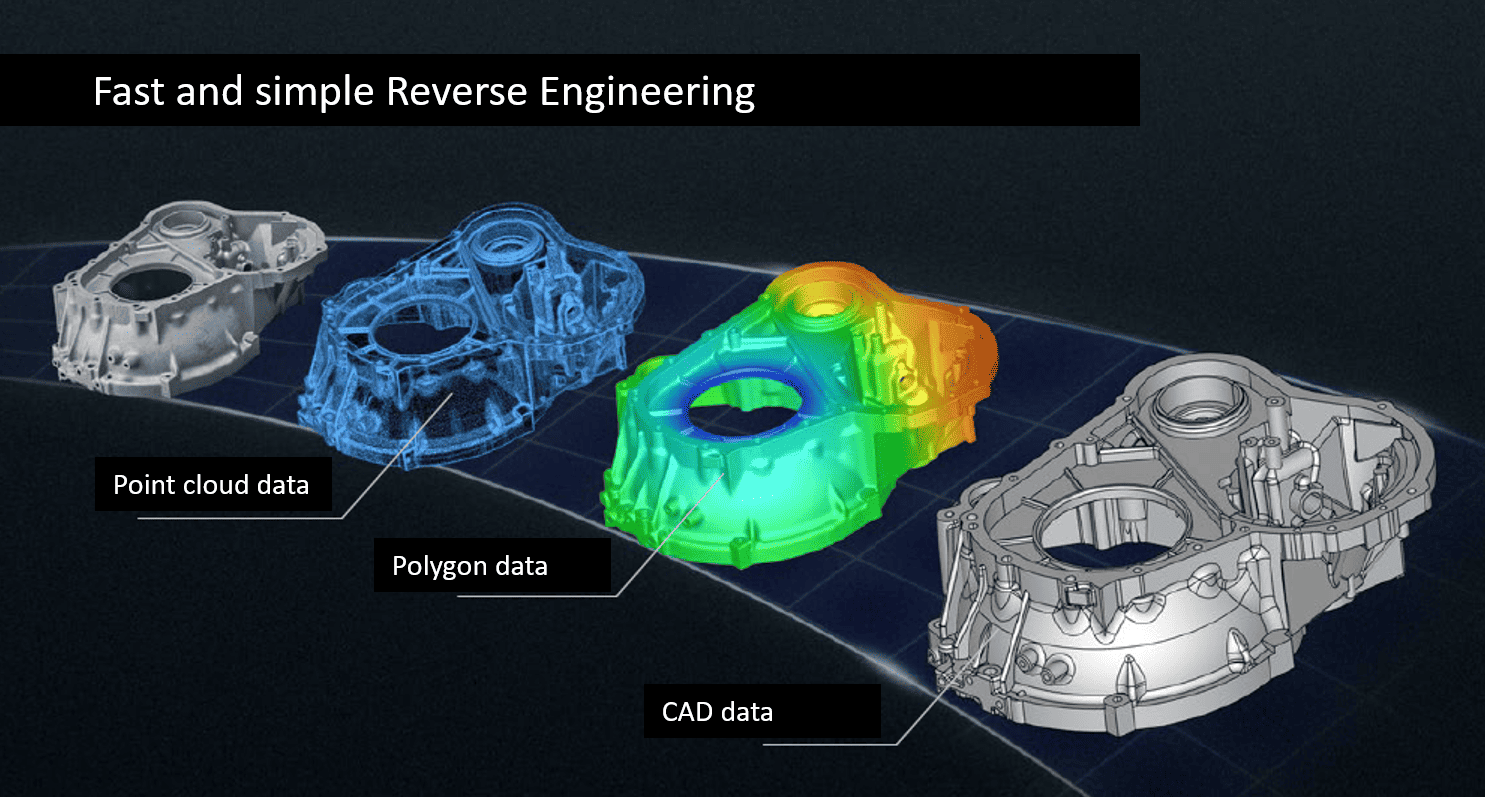

3D printing and reverse engineering – old components new in series production

Reverse engineering is an innovative method that enables us to analyse and understand existing technologies, components or products and then reconstruct them in improved or optimized versions. As your reliable engineering partner, we use reverse engineering to revive existing components, optimize existing solutions, promote innovation and develop tailor-made solutions.

As soon as a component has been newly digitized and specified, we suggest a suitable manufacturing process to our customers in order to realize series production. If required, 3D printed samples can be produced in advance to compare the original part with the replica. However, 3D printing is not worthwhile for most components in series production; we often have a better solution for this.

In order to provide our customers with the best possible support, our engineering office is equipped with a 3D scanner, 3D printer, a high-resolution digital microscope and a material analysis device for plastics. The 3D scan provides us with the geometry and the material analysis tells us the material of the existing component, if this is not known.

For more info:

Our philosophy is to offer our customers reverse engineering, material analyses of plastics, digital microscopy and component optimization free of charge, provided there is a realistic chance of subsequently receiving the series order.

3D Printing and more: What we offer our customers

- Free advice on economical series production of your components and products

- Reverse engineering to bring old parts back into series production

- 3D scans and 3D measurements with a measuring accuracy of ±10µm, non-destructive

- Digital microscopy for structural analyses with 20-200x magnification

- Material analyses of plastics and additives

- 3D scanners, 3D printers, 4K high-performance microscopes, material analysis devices, electrical measuring devices and much more

- We have in-house and are therefore not reliant on external laboratories. This saves our customers time and money.

- CAD design and drawing creation

- Advice on material selection and manufacturing processes

- Series production of small and large batches for all industries

- International series supply including the associated logistics

- Standardized processes based on common automotive standards

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.