Customized solutions for demanding industrial applications

In modern industry, bellows play an indispensable role in protecting critical machine parts from environmental influences, contamination and mechanical wear. These flexible connecting elements provide effective sealing and movement compensation in a wide range of applications, from the automotive industry to highly specialized mechanical and plant engineering. Bellows made of high-quality materials such as EPDM, VMQ (silicone), NR, NBR, PVC, NBR/PVC, CR and TPE, which offer specific properties for a wide range of operating conditions, are particularly in demand.

Bellows have two essential functions: To protect the operator and to protect the machine. Depending on requirements and needs, we develop and manufacture ready-to-install bellows systems made of rubber and fabric. We can produce customized rubber sleeves for small and large series with simple means.

Variations of the bellows

Rubber bellows

A rubber bellows, rubber sleeve or spacer is a folded rubber component which flexibly adapts its size to the circumstances. They often serve to protect movably mounted components (e.g. guides and joysticks). Due to the flexible cover, no dirt can get in and impair the function, nor can an operator be injured on the machine.

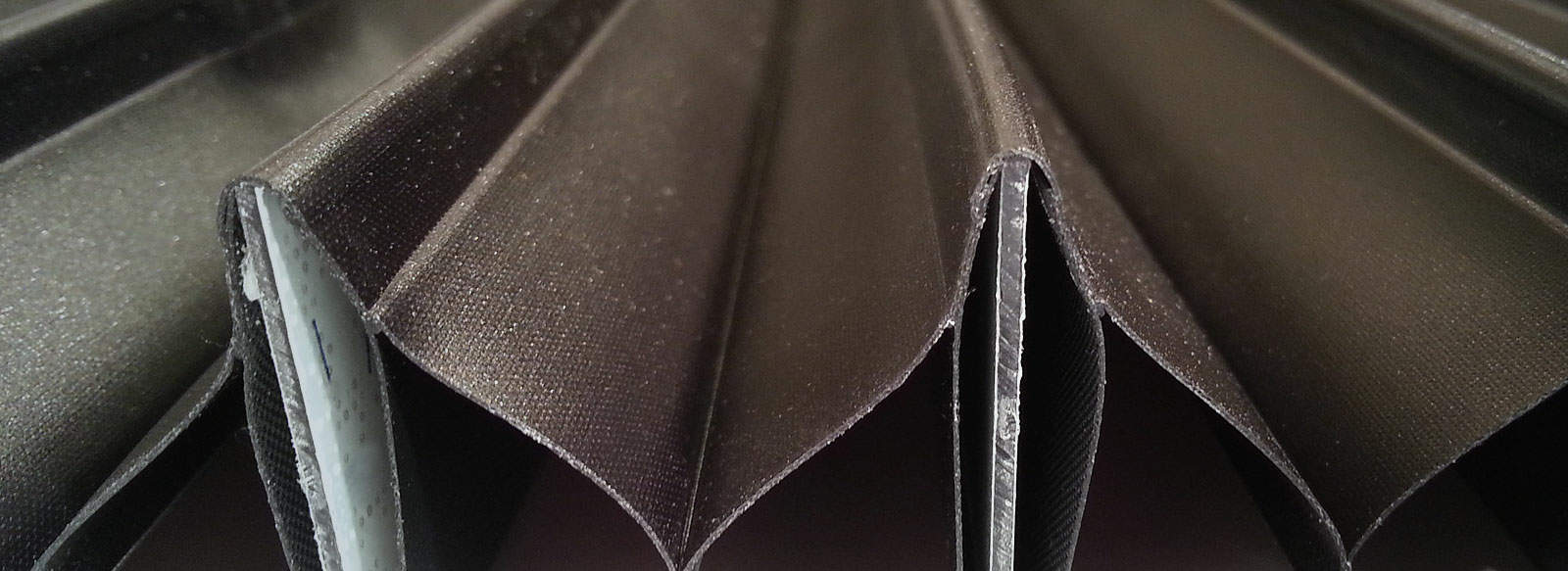

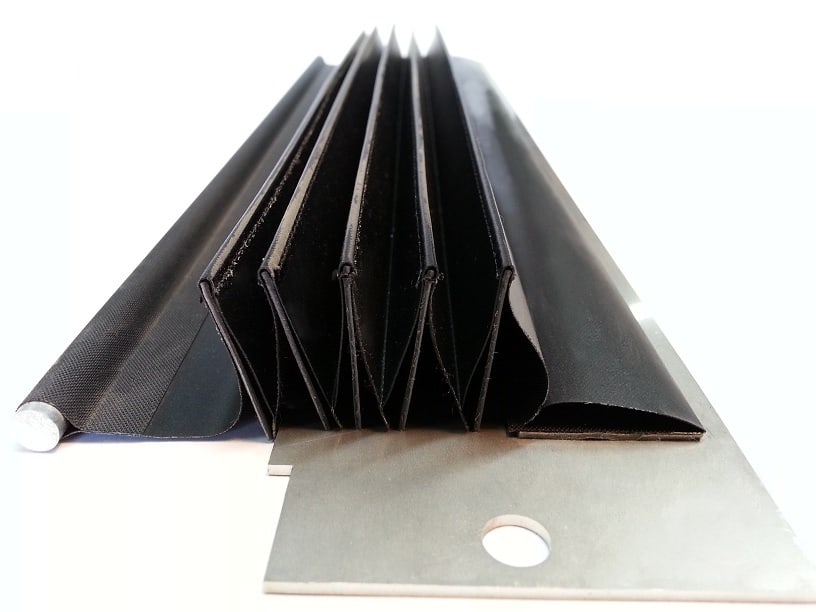

Fabric bellows

Cuffs made of fabric can be produced comparatively easily, even in large dimensions, without any gaps. This is made possible by a sophisticated manufacturing process that has been perfected over many years. Small and large series can be produced with a flexible number and width of pleats.

Tailor-made bellows according to customer specifications

The majority of our custom rubber bellows are made of silicone or EPDM. These are manufactured as Moulded Rubber Parts, whereby the geometry can be flexibly adapted to your requirements. We would be pleased to provide advice on this without obligation – also for smaller quantities.

We manufacture larger bellows and covers from tarpaulins, foils or textiles or composite materials. During production, folds of a specified length are joined together by high-frequency welding. If required, the folds can be reinforced by additional dying. This flexible bellows system is versatile and quickly available.

Materials

- Silicone (VMQ)

- TPU

- TPE

- EPDM

- HNBR

- NBR

- PVC

- NR

- CR

Fields of application

- Protection of bridge bearings against birds

- Operator protection for machines and systems

- Protection against weathering

- Dust cover

- Splash guard

- Protection of moving elements

- Protection against contamination

- Privacy

- Sun protection

Variety of materials for specific requirements

- EPDM (ethylene propylene diene monomer): EPDM bellows are characterized by their excellent resistance to weathering, ozone and temperature extremes. They are ideal for outdoor applications or in areas with high temperature fluctuations.

- NR (natural rubber): NR offers outstanding elasticity and tear resistance, making it particularly suitable for applications where high flexibility and cushioning are required.

- NBR (nitrile butadiene rubber): NBR is known for its resistance to oils, greases and other hydrocarbons, making it a preferred choice for the automotive and engineering industries.

- PVC (polyvinyl chloride): PVC bellows offer a cost-effective solution with good chemical resistance and are easy to work with, making them attractive for a wide range of applications.

- CR (chloroprene rubber): CR combines flame resistance with good weathering and ozone resistance, ideal for use in demanding environments.

- TPE (thermoplastic elastomers): TPE combines the processing advantages of thermoplastic materials with the elastic properties of elastomers, enabling fast and efficient manufacturing processes.

- VMQ (silicone rubber): Silicone is characterized by its excellent resistance to heat and cold, making it ideal for extreme temperature applications. Silicone also has good resistance to ozone and weathering.

Why bellows?

Bellows are not only used to protect mechanical components, but also to extend the service life of machines and systems. They compensate for movements between two elements, absorb vibrations and minimize the ingress of moisture, dust and other contaminants. Their flexible design allows them to adapt to different configurations, making them an ideal solution for complex industrial requirements.

Your partner for customized bellows solutions

As a leading supplier of bellows, we understand the importance of quality, reliability and customized production. Our expertise enables us to develop the optimum bellows for every application and environment. Whether you need a solution for extreme temperatures, aggressive chemicals or special movement profiles, we offer you the right solution from a single source.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.