We develop and manufacture extruded as well as coiled moulded hoses of various qualities. The range of applications extends from automotive and machinery to air conditioning systems. The media carried can be liquid, gaseous, oily, aggressive, cold or hot. We find a reliable solution and support our customers from development to series production.

Customer-specific moulded hoses – With us there is nothing off the peg.

Individual hoses for large and small series

Provided that the geometry and material are defined, we manufacture according to drawings. If, however, only the target is specified (e.g. to replace piping with an inexpensive moulded hose), we support our customers from the choice of material to the design in CAD (Creo 3.0). Resistance to chemical substances and acids can be achieved by special material mixtures and structures.

- EPDM can be used for hoses with operating temperatures up to 120 °C

- Silicone can be used up to 200 °C

Material overview of our moulded hoses

- EPDM

- NBR

- HNBR

- Silicone

- AEM

- NBR/PVC

- ECO

- CSM

- CR

- FPM

Our possibilities

- peroxide cross-linked / sulphur cross-linked

- fuel resistant / chemical resistant materials

- with and without fabric reinforcement / spirals

- Hoses as required also with threaded inserts, branches and sleeves

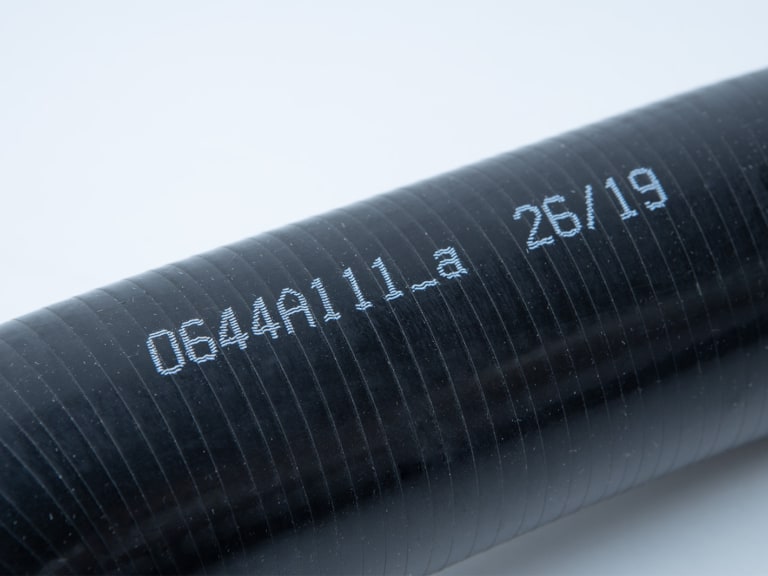

- printed moulded hoses

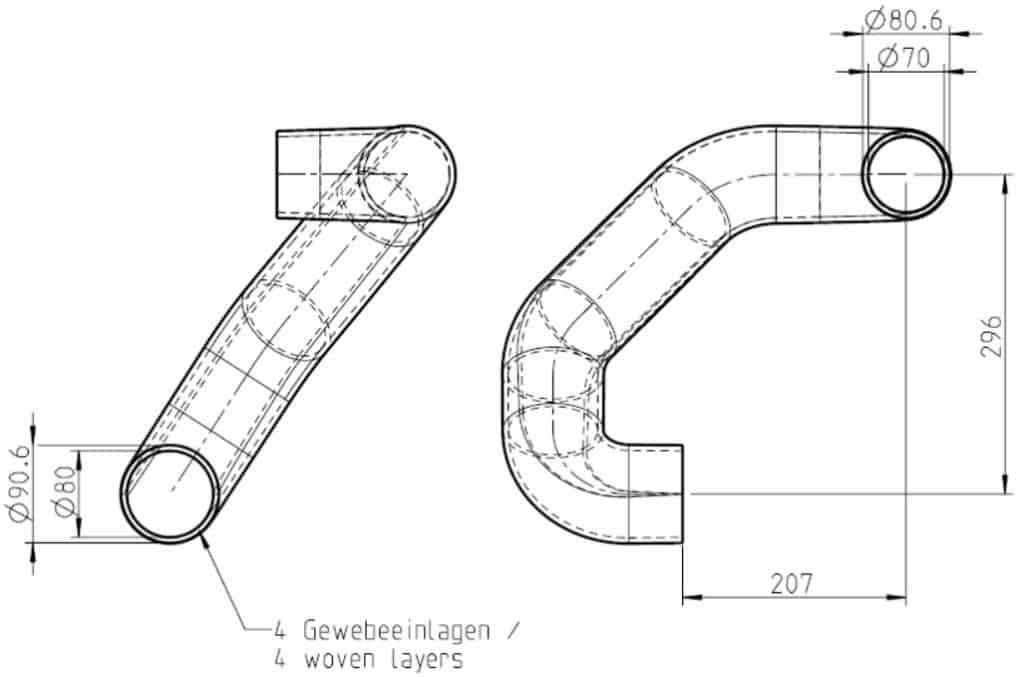

Fabric-reinforced hoses

Depending on requirements, hoses must be reinforced with fabric inserts or spirals. In order to withstand higher pressure, fabric inserts of polyester or aramid can be used, for example. Against negative pressure (e.g. with suction hoses), spirals can be used to prevent the hose from collapsing.

Application of moulded hoses

- Suction Hoses

- Radiator Hoses

- Tank hoses

- Heating hoses

- Climatic hoses

- Waste water hoses

- Turbocharger hoses

- Ventilation hoses

- Suction hoses

Process for the manufacture of moulded hoses

Extrusion

- Extrusion of the tube core (inner layer)

- Mount the fabric reinforcement (pressure carrier)

- Extrusion of the hose cover (outer layer)

- Mounting of the blank on mandrel tool with corresponding geometry

- Vulcanization of the hose in the autoclave

- Demoulding

- Cutting

Wrapping

- Spiral wrapping of the mandrel tool with rubber bands

- Connection of the belts by vulcanization

- Demoulding

- Cutting

The extrusion can be carried out either on mandrel tools or without mandrels. Extruded hoses have a smooth or grooved surface and are cheaper than wound hoses due to the simple manufacturing process.

Wrapped molded hoses have a fabric structure on the outside and are usually of higher quality. They are characterised by a special dimensional accuracy, which is reflected not least in the price.

Why use molded hoses?

Molded hoses play a critical role in numerous industries, including automotive, mechanical engineering and aerospace. These custom-made hoses are tailored to meet the unique requirements of different applications and equipment. They offer an optimal solution for conveying liquids and gases in complex systems. Find out below why molded hoses are essential for your business and how they can help increase efficiency and reduce costs.

Molded hoses are characterized by their flexibility and resistance to high temperatures, pressure and aggressive chemicals. These properties make them an ideal choice for demanding industrial applications. Their customized design allows them to be installed in tight or unusually shaped spaces where standard hoses would not fit. This enables seamless integration into existing systems and helps to optimize space requirements. In addition, they compensate for environmental tolerances as they have a certain degree of flexibility.

The use of molded hoses can also extend the service life of your machines and systems. By being precisely tailored to the specific needs of your systems, they minimize the risk of leaks and failures that can be caused by unsuitable hose connections. This results in lower maintenance requirements and reduced operating costs.

For companies that focus on sustainability and efficiency, molded hoses offer an excellent solution. Not only are they durable, but they are also reusable and recyclable, making them an environmentally friendly option. In addition, they improve the energy efficiency of your systems by ensuring the smooth transport of media and minimizing energy losses.

In conclusion, molded hoses are a key component for modern industrial applications. Their customized adaptability, durability and efficiency make them an essential investment for any company looking to increase productivity while reducing costs. By choosing high-quality molded hoses, you are ensuring a reliable, long-lasting solution that is tailored specifically to your company’s needs.

For more information about molded hoses and how they can be used in your business, please contact us – we will be happy to provide you with constructive advice.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.