Seals, profiles, profile gasket, sealing profile or rubber gasket – there are many names and yet in the end they all mean the same thing. Most of them are inconspicuous, elastic components that nobody notices. Seals are often only noticed when they no longer seal and components fail as a result. We support our customers from the development to the production and think not only of an economical production but also of a simple and safe assembly.

Overview of our Seals

There are usually three types of gaskets: extruded, punched and formed. They differ mainly in their manufacturing process. The tasks of seals are usually the same – sealing, reducing vibration and reducing noise. We will be happy to discuss with you personally which seal is best suited to your application.

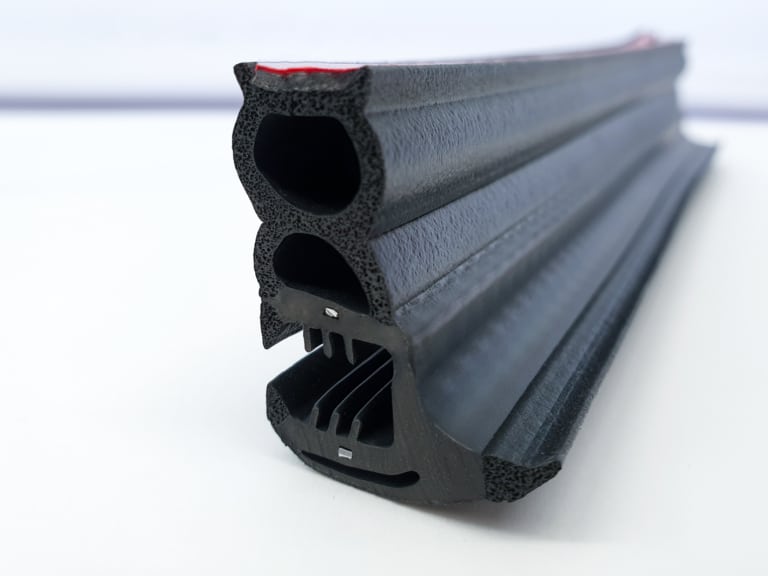

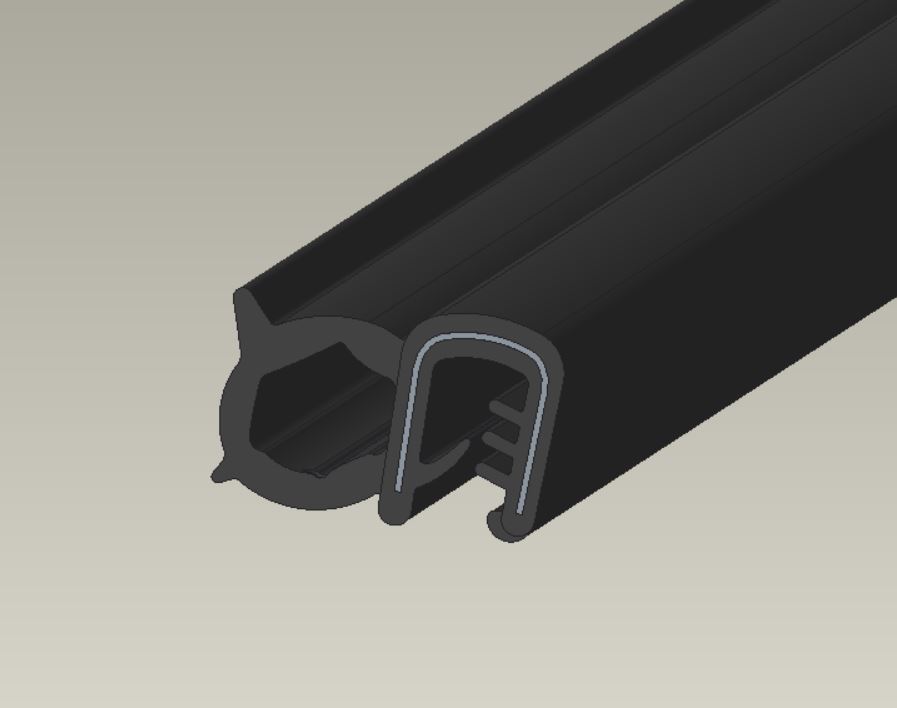

Extruded seals

Two-dimensional gasket cross-sections (profiles) are usually extruded and supplied as yard ware on a roll or cut to size. Cost-effective and fast production allows gaskets to be manufactured in large quantities. At the same time, the tooling costs are rather low. Typical applications are extruded door seals, window seals and frame seals. The latter can be produced in conjunction with vulcanized moulded corners or by gluing. Self-adhesive tapes can be applied hot or cold to the sealing profiles and guarantee a safe installation.

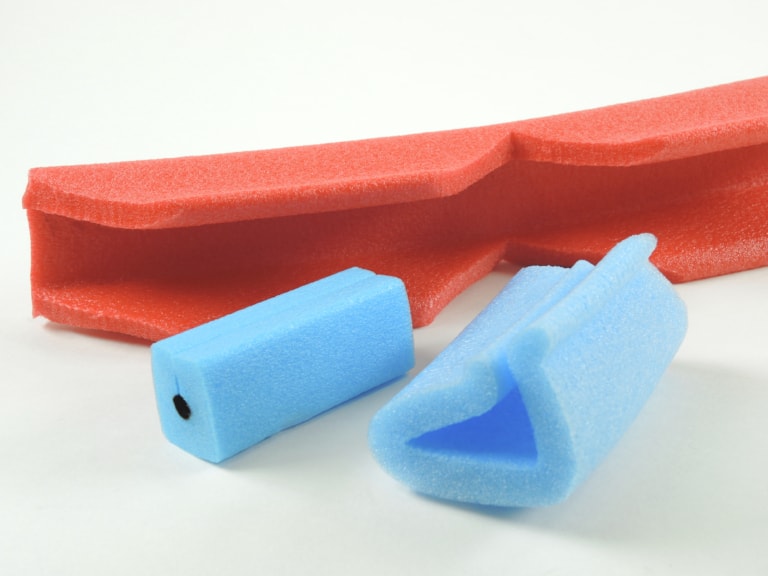

Moulded gasket parts

Moulded gasket parts or even Moulded Rubber Parts are always used when space conditions make it necessary because two-dimensional gasket cross-sections are no longer sufficient. Since the gaskets, some of which are very complex, cannot be extruded, they must be vulcanized in molds. Classic moulded parts are grommets for cables, Rubber Bellows, sleeves or moulded corners for frame seals. The tool costs for these are usually manageable.

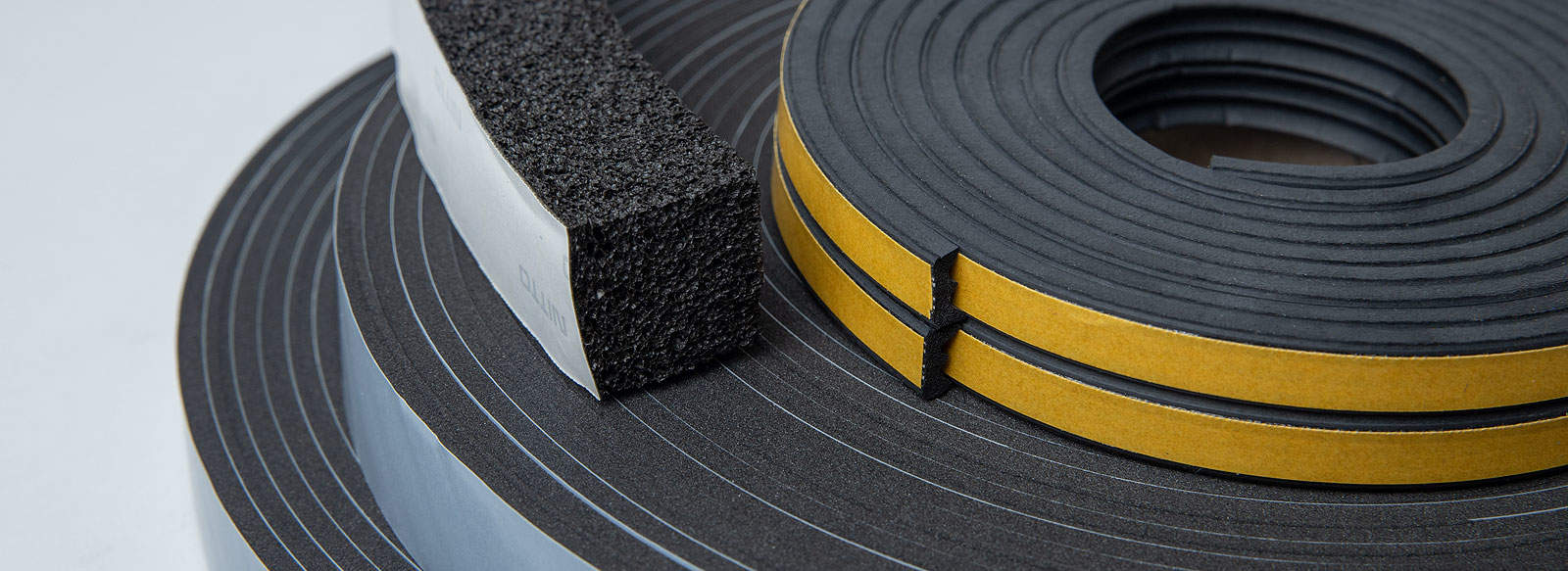

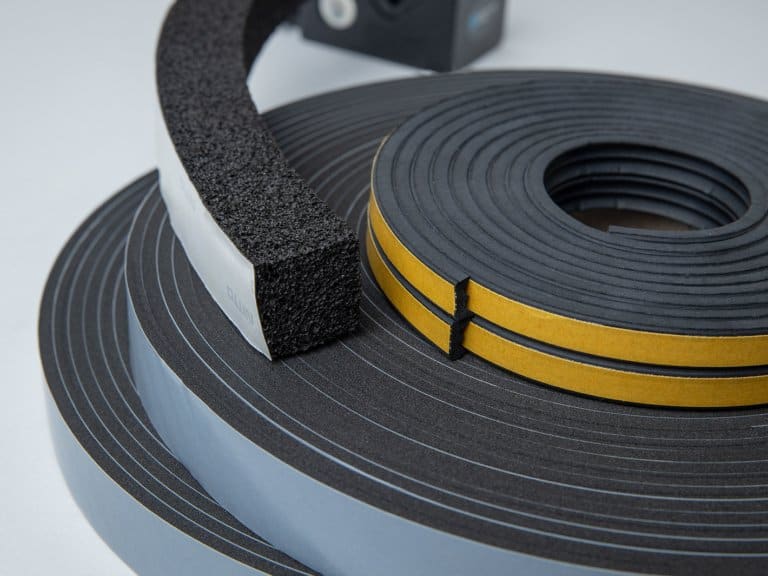

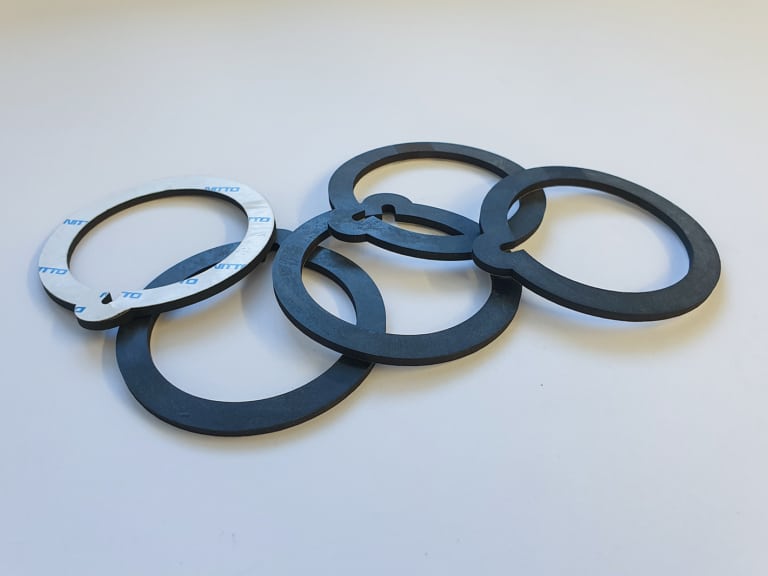

Stamped gaskets

Stamped gaskets are characterized by a simple, two-dimensional geometry. Besides sealing, they are often used for damping and vibration reduction. The material thickness is usually between 1.0 – 6.0 mm. The use of sponge rubber and cellular rubber is widespread, preferably in combination with a self-adhesive foil. A punching tool is required for punching – the costs are quickly amortized over the number of pieces. Smaller quantities can be produced economically with water jet cutting.

Special designs:

- Sponge rubber seal / cellular rubber

- Fabric reinforced / metal insert

- Self-adhesive seals

- Flocked gaskets

- Sliding seals (bonded coating)

Special designs:

- Sponge rubber seal / cellular rubber

- Inserted metal parts

- Self-adhesive seals

- Flocked gaskets

- Sliding seals (bonded coating)

Special designs:

- Sponge rubber seal / cellular rubber

- UL-certified

- Self-adhesive

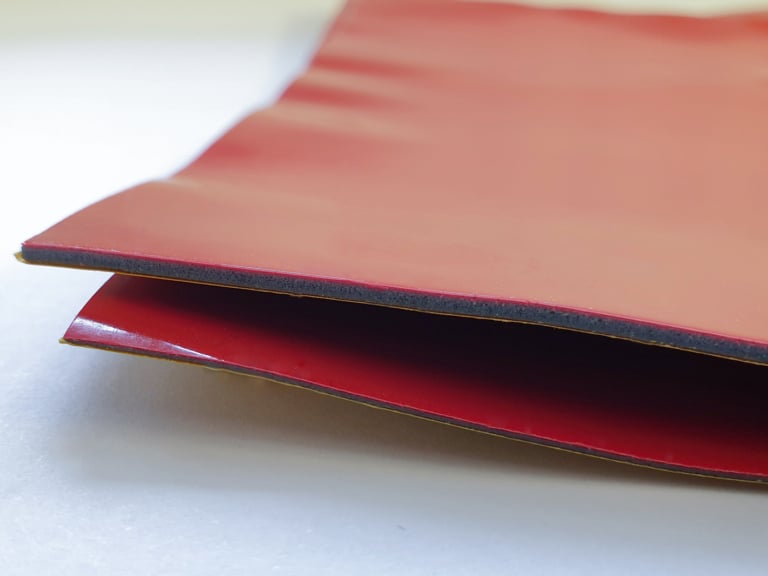

Self-adhesive sealing systems: Functional bonding vs. Assembly aid

With self-adhesive seals, a distinction is made between functional bonding and pure assembly aids. Functional bondings must adhere reliably over the entire product life, which leads to significantly higher demands on the adhesive. Mounting aids serve purely to improve mountability. After assembly, the adhesive bond has no further function.

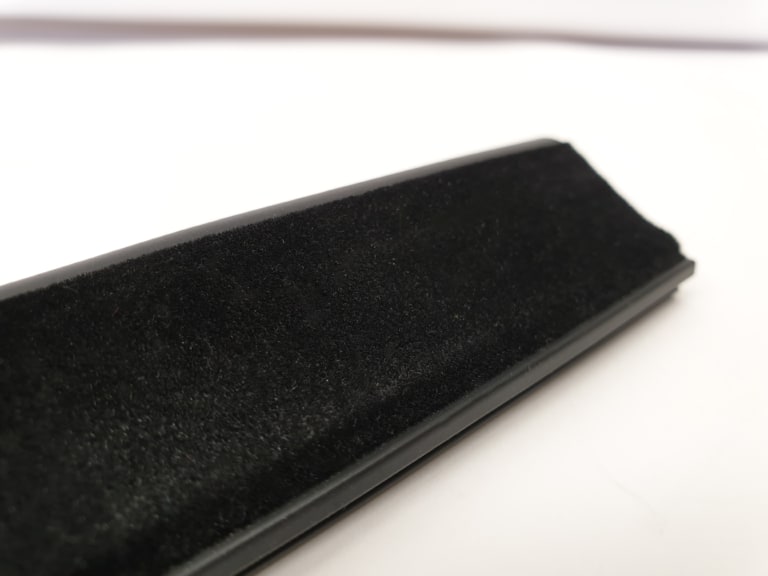

Flocked gaskets

The electrostatic flocking of seals and profiles reduces the friction between the profile and, for example, a window pane, although the sealing effect is maintained. In addition, the flocking compensates for the production-dependent tolerances.

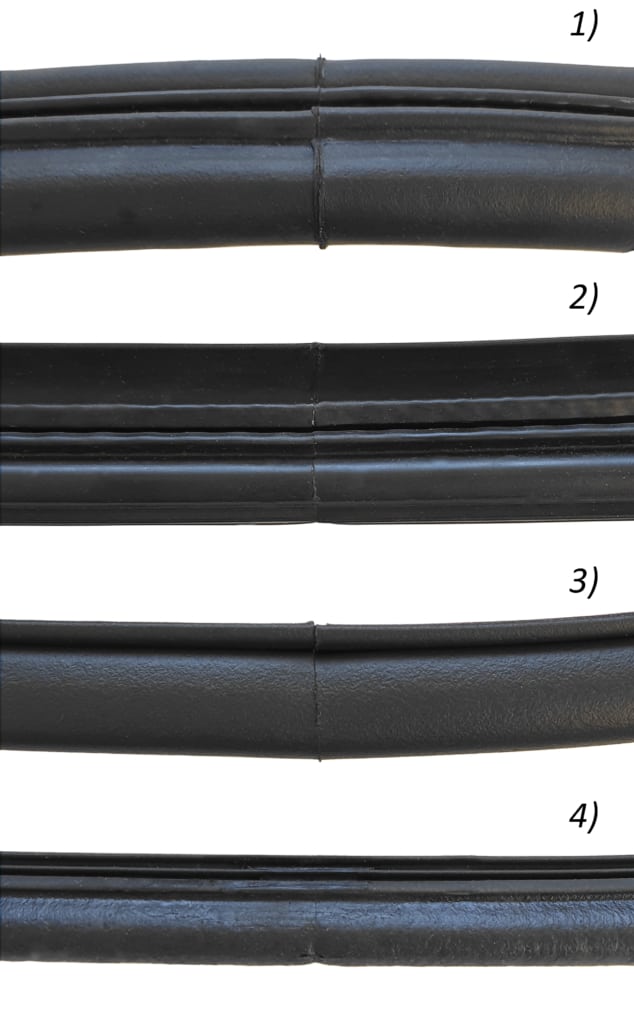

Production of rings and frame seals

Profiles can be butt-jointed using different methods. In this simple way, frames and rings can be created from seals. Depending on the requirements and quantity, we advise our customers and recommend the most economical variant.

- Joints bonded with EPDM foil

- Joint glued

- Joint welded with PE-foil

- Joints vulcanized

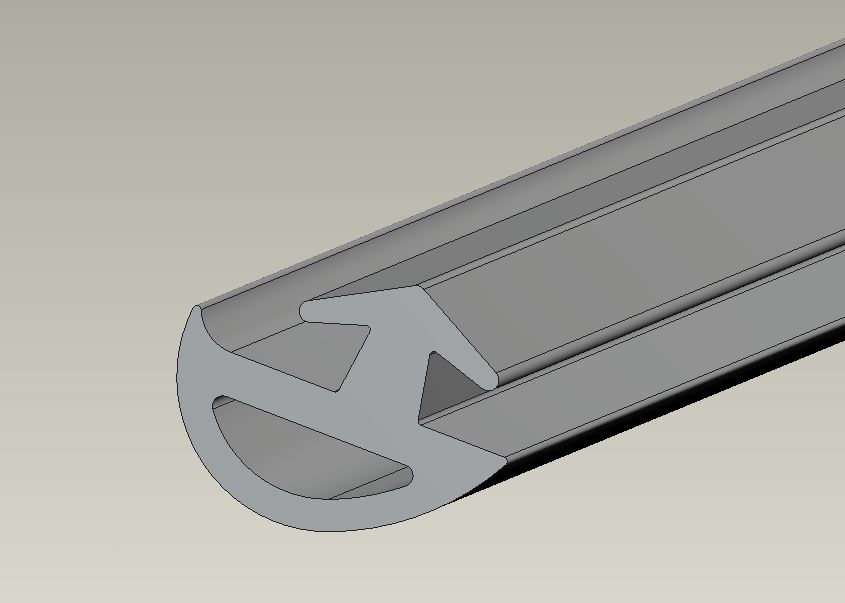

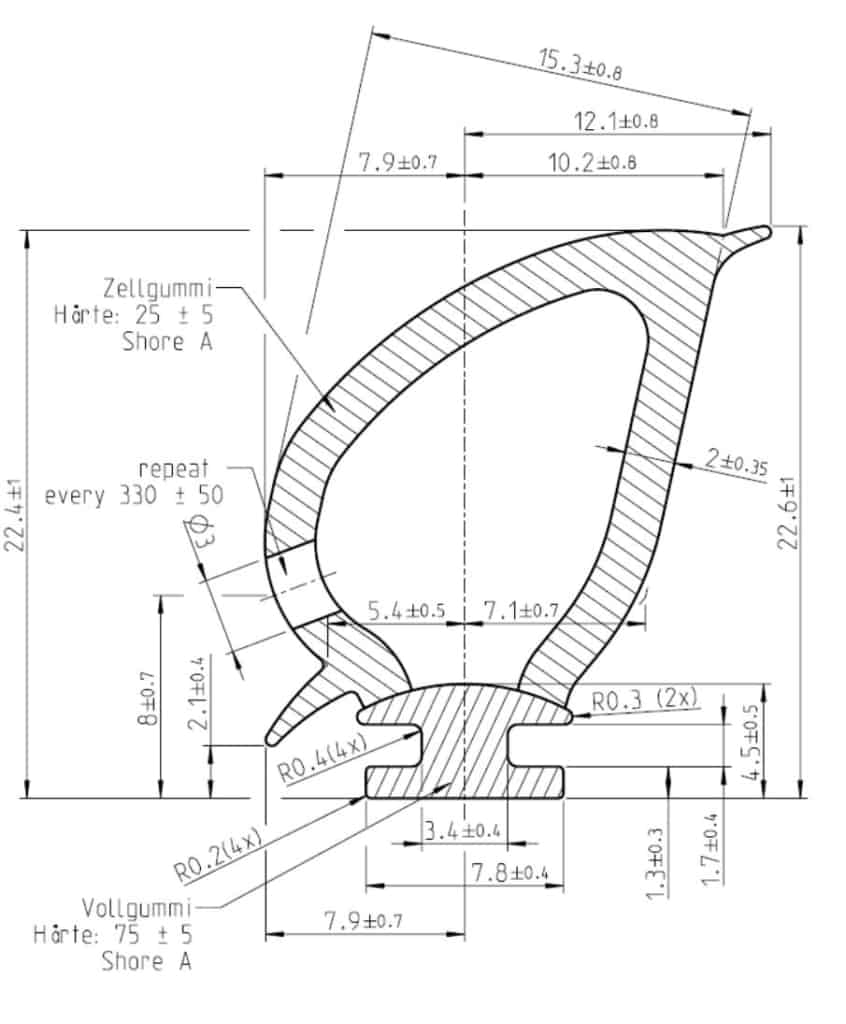

Development of seals and profiles

For more than 25 years we have been developing and manufacturing seals and rubber moulded parts for demanding customers, mainly from the automotive industry. With modern CAD software (Creo 3.0) we can design gaskets precisely, even for large assemblies. In efficient cooperation with our customers, we find an economical solution and then implement it as quickly as possible.

We would also be pleased to advise you on self-adhesive and flocked seals. We are sure to find a suitable adhesive tape for your application, which can be applied cold or hot as required.

Tolerances in rubber technology

If elastic rubber components are to be used precisely because of their high deformability, this property has a detrimental effect in production. Rubber parts cannot be manufactured with the same tolerances as those used to produce milled parts. We manufacture our rubber parts according to ISO 3302-1.

Typical materials for seals

- EPDM

- TPE

- CR

- FKM/FPM (Viton)

- Foam rubber

- Cellular rubber

- Material mix

- PVC

- Silicone

- NBR

- NR

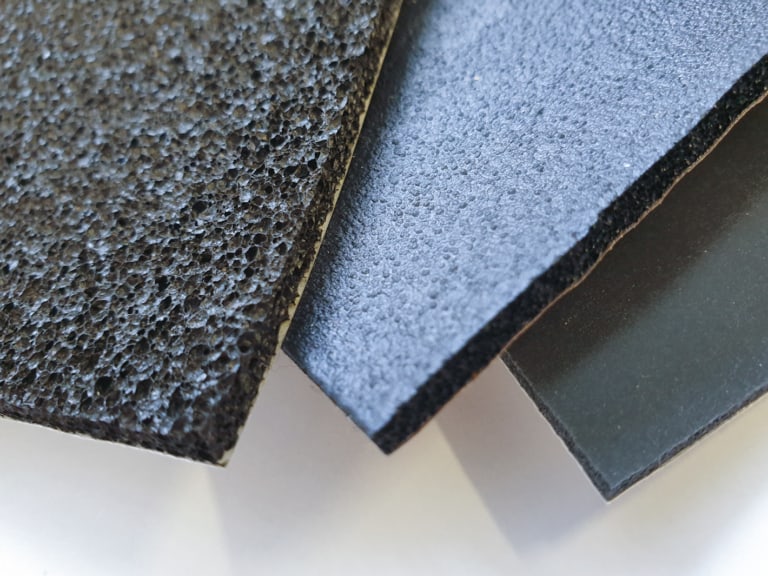

Difference between sponge rubber and cellular rubber

Visually, sponge rubber and cellular rubber are very similar and are made from the same raw materials – often EPDM, CR, NR, NBR and SBR. The differences are hidden inside the cell structure. This is due to the different manufacturing processes. Sponge rubber is made of embossed rubber, has open cells and a dense outer skin. Once the outer skin is damaged, water can penetrate into the open cell structure, comparable to a sponge. Cellular rubber, on the other hand, has no outer skin, which means that the surface can easily be damaged. Water cannot penetrate through the porous but closed-cell structure.

Seals made of sponge rubber and cellular rubber seal best at a component compression of 30 to 50 %.

Material properties of important elastomers

| Material | Natural rubber | Styrene butadiene rubber | Ethylene propylene diene rubber | Isobutene-isoprene rubber | Chloroprene rubber | Epichlorohydrin rubber | Acrylonitrile butadiene rubber | Hydrogenated acrylonitrile-butadiene rubber | Ethylene acrylate rubber | Fluororubber | Silicone | Fluoromethyl polysiloxane | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Short Name | NR | SBR | EPDM | IIR | CR | ECO | NBR | HNBR | AEM | FPM / FKM | VMQ / MVQ | FVMQ | |

| Hardness Shore A | 30-90 | 35-90 | 30-90 | 30-80 | 25-90 | 40-90 | 30-95 | 45-98 | 40-90 | 40-90 | 30-85 | 30-80 | |

| Therm. Behaviour | flexible to °C | -55 | -30 | -50 | -60 | -40 | -40 | -30 | -45 | -30 | -20 | -55 | -55 |

| max. Permanent use to °C | 80 | 100 | 130 | 130 | 100 | 130 | 110 | 150 | 150 | 200 | 210 | 190 | |

| Resistance | Fuel | --- | -- | --- | -- | + | ++ | ++ | + | -- | +++ | -- | +++ |

| Mineral oil at 100 °C | --- | -- | -- | --- | + | +++ | +++ | ++ | +++ | +++ | ++ | +++ | |

| Acids | - | - | +++ | +++ | ++ | +++ | ++ | +++ | + | +++ | - | + | |

| Leaches | ++ | ++ | +++ | +++ | ++ | ++ | --- | + | -- | +++ | -- | + | |

| Water (at 100 °C) | -- | -- | +++ | ++ | + | ++ | ++ | +++ | + | ++ | ++ | ++ | |

| Weather and ozone | - | - | +++ | + | ++ | +++ | -- | +++ | ++ | +++ | +++ | +++ | |

| UV | - | - | ++ | + | + | - | - | +++ | + | +++ | +++ | +++ | |

| Gas impermeability | -- | - | - | +++ | + | ++ | ++ | ++ | + | +++ | --- | + | |

| Food suitability | yes | yes | yes | yes | yes | no | yes | no | no | yes | yes | yes | |

| +++ | excellent | - | satisfying | ||||||||||

| ++ | good | -- | bad | ||||||||||

| + | ok | --- | insufficient | ||||||||||

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.