We support our customers quickly, energetically and without restrictions

As an independent development partner and series supplier, we always aim to provide our customers with the best technical and most economical solution.

We develop and compare different approaches in terms of applicable materials, manufacturing processes, supply chains, administrative effort and potential risks. After all, the best technical solution is useless if it cannot also be implemented economically. Meeting this challenge with pleasure every day makes the difference. Our new slogan “Creating hidden solutions” demonstrates how seriously we take this idea.

“We do not sell a solution because a machine has to be used to full capacity, but we sell the best solution for the entire system and thus also for the customer.”

Our services in overview

Competent planning and development

We usually provide the planning and development services free of charge, provided that the costs are kept within reasonable limits and there is a realistic chance of receiving the series order. You can find examples of already implemented developments under Assembly of Components. We would be happy to advise you without obligation!

- Fast, personal and free advice

- Professional 3D scans and 3D measurement in-house

- Digital microscopy for structural analysis

- CAD design (Creo 8.0) including drawing creation

- Prototyping with our own 3D printers (SLA and FDM)

- Component research

Economic production and automated processes

Progress is only achieved through constant adaptation and improvement. We have been following this credo for over 25 years. Our modern ERP system from Dontenwill provides us with the necessary transparency to identify potential problems at an early stage. For this reason, we are constantly developing our system further in order to always be a few steps ahead of the competition. This continuous improvement process is also reflected in the economical production.

- Production individually adapted to product complexity and quantity requirements

- Automatic batch traceability

- Production and processes according to automotive standards

- Flexible capacity planning

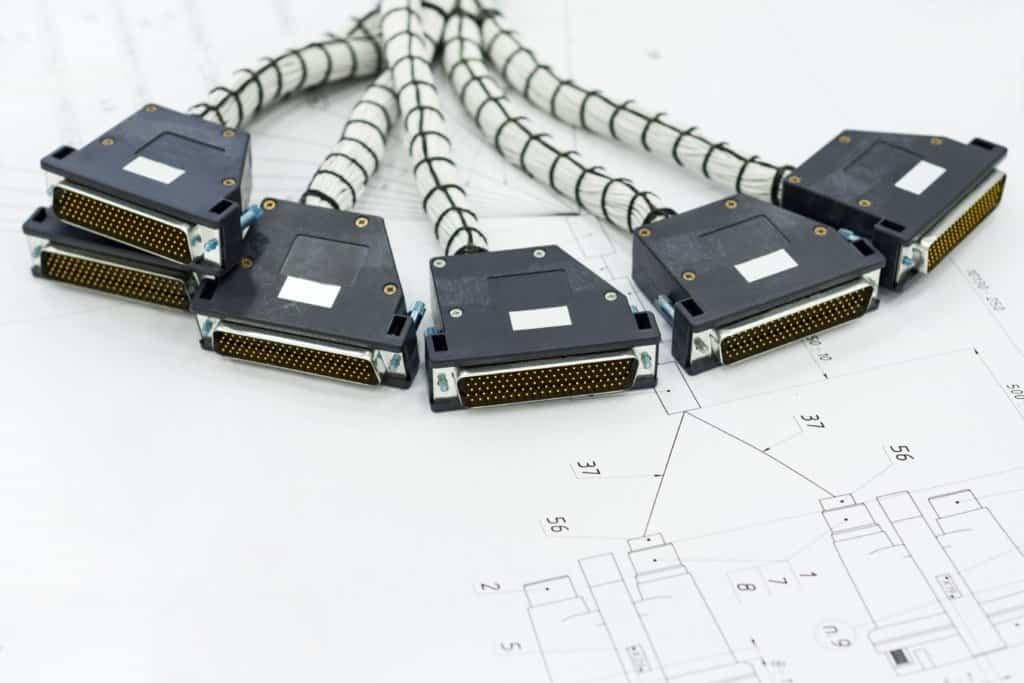

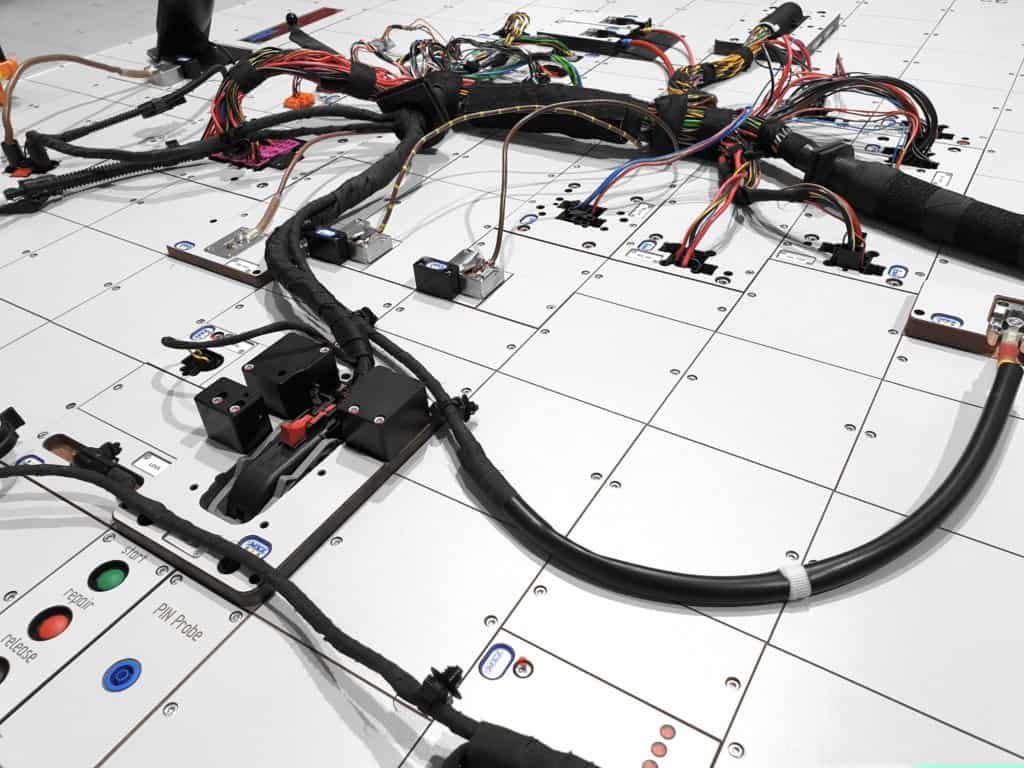

Flexible component assembly

In addition to the pure production of individual parts in the areas of Cable Assembly, Plastics Technology and Metal Working, we also assemble these into ready-to-install assemblies if required. Furthermore, we also offer the assembly of components as contract manufacturing. We assemble simple and complex assemblies in large and small series production across all industries.

The traceability of individual parts is always guaranteed by our modern and transparent processes.

- Assemblies with electronic parts, plastic parts and metal parts

- Simple and complex assemblies, also as variants

- Testing of the overall system

- Customized assembly

- Packing the modules

Highest quality standards

Consistently high quality standards are also expected in economical production. In order to maintain these standards, we always strive not only to use the regular Certifications as an opportunity to optimize our internal processes, but also to ask the people who work with the components every day for their opinion.

- Regular certifications, employee training and audits

- Initial sample inspection reports (ISIR) are created as standard

- 8D-Report is no foreign word for us

- Processes according to automotive standards

- Specially developed QM module as part of our modern ERP system

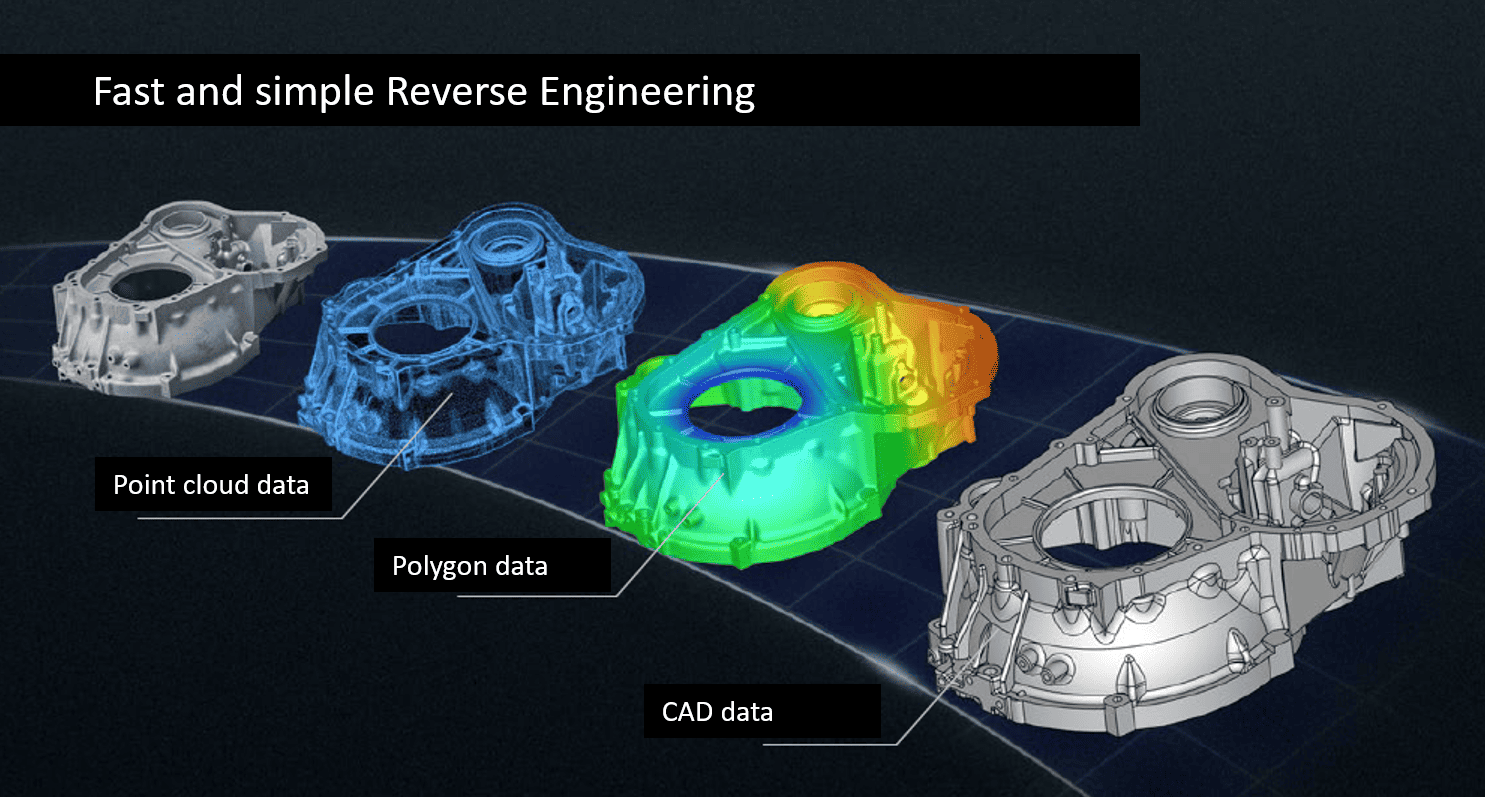

Reverse engineering – old components brought back into series production

Reverse engineering is an innovative method that enables us to analyse and understand existing technologies, components or products and then reconstruct them in improved or optimized versions. As your reliable engineering partner, we use reverse engineering to revive existing components, optimize existing solutions, promote innovation and develop tailor-made solutions.

In order to provide our customers with the best possible support, our engineering office is equipped with a 3D scanner, 3D printer, a high-resolution digital microscope and a material analysis device for plastics. The 3D scan provides us with the geometry and the material analysis tells us the material of the existing component, if this is not known.

For more info:

Quick facts – Reverse Engineering

- Technologies such as artificial intelligence (AI) and machine learning are making reverse engineering more precise and efficient.

- Often used to breathe new life into discontinued series and spare parts.

- The most important tools for reverse engineering include CAD software, 3D scanners, 3D printers, material analyzers, microscopes, hardness testers, color fans and electrical analyzers

- usually less complex than many customers would think

Our philosophy is to offer our customers reverse engineering, material analysis of plastics, digital microscopy and component optimization free of charge, provided there is a realistic chance of subsequently receiving the series order.

Flexible supply logistics for international series production

Thanks to our own fleet of vehicles, we are able to supply our customers independently. This applies in particular to the area of Southern Germany and Austria. There, we cover regular trips between different production sites of our customers ourselves and, if desired, we can flexibly reschedule if the demand should change at short notice. The flexibility we have gained, increased reliability and shorter reaction times have made us a strategic supplier in recent years. We are aware of this responsibility and implement the necessary measures early and consistently. This also includes a daily risk analysis in order to identify supply bottlenecks at an early stage and initiate appropriate countermeasures. We are supported in this by our ERP system, which automatically triggers a warning through intelligent algorithms.

If required, we also take care of the worldwide supply logistics of your plants – whether by air, sea, rail or road – we will find the best solution.

- Responsibility for international supply logistics

- Short delivery times thanks to own truck

- High delivery reliability

- Versatile packaging options

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.