In a world where precision and innovation are crucial, digital microscopy gives us unprecedented detail and insight into microscopic worlds. From material analysis to quality control, we offer comprehensive solutions tailored to the specific requirements of our customers.

If a classic microscope with high magnification is combined with a high-quality camera, a sample can be viewed directly on a screen. This makes day-to-day work easier when dealing with samples, measurements and the associated digital documentation.

- Precision and clarity: Our state-of-the-art digital microscope provides razor-sharp images and enables detailed analysis of material structures.

- Versatility: Whether it’s for examining materials, quality assurance in production or scientific research – we adapt to your requirements.

- Experience and expertise: As an established engineering company and system supplier, we bring extensive experience and in-depth expertise to materials and manufacturing processes.

Our digital microscopy services:

- Material analysis: Examination of materials down to microscopic level for comprehensive insights into structure and properties.

- Quality control: Precise inspection of production processes and materials to ensure the highest quality standards.

- Research and development: Support for innovation projects through the detailed analysis of microscopic structures.

Images and analyses with high-resolution 4K digital microscopy are free of charge if required for new or existing projects.

Quality assurance with digital microscopy

In a world where precision makes all the difference, quality assurance is of crucial importance. With high-resolution digital microscopy, we offer our customers a way of guaranteeing the highest quality standards during series production.

Digital microscopy enables a detailed and high-resolution analysis of material structures. Irregularities, defects or deviations can be detected from the surface down to microscopic details. This enables us not only to check the visible quality, but also to analyze microscopic features that can be decisive for the overall quality.

Advantages of quality assurance through digital microscopy:

- Precise inspection: The high-resolution images from our digital microscope allow us to see the smallest details and carry out inspections with unprecedented precision.

- Efficient defect detection: Early detection of defects and deviations enables prompt correction and minimizes rejects, resulting in more efficient production.

- Documentation and analysis: Our digital microscopy not only captures images, but also allows the results to be documented and analyzed. This is crucial for continuous improvement and traceability.

Applications:

- Analysis of microstructures for quality assurance in production

- Detection of material defects and irregularities

- Inspection of surface quality and coatings

Quality begins with precision – experience the future of quality assurance with digital microscopy, material analysis and 3D scans and 3D measuring.

Quick facts – Digital microscopy

- 20 to 200x magnification

- 2D and 3D observations and measurements possible

- Very high depth of field throughout

- Reduction of reflections

- Wide range of measurements

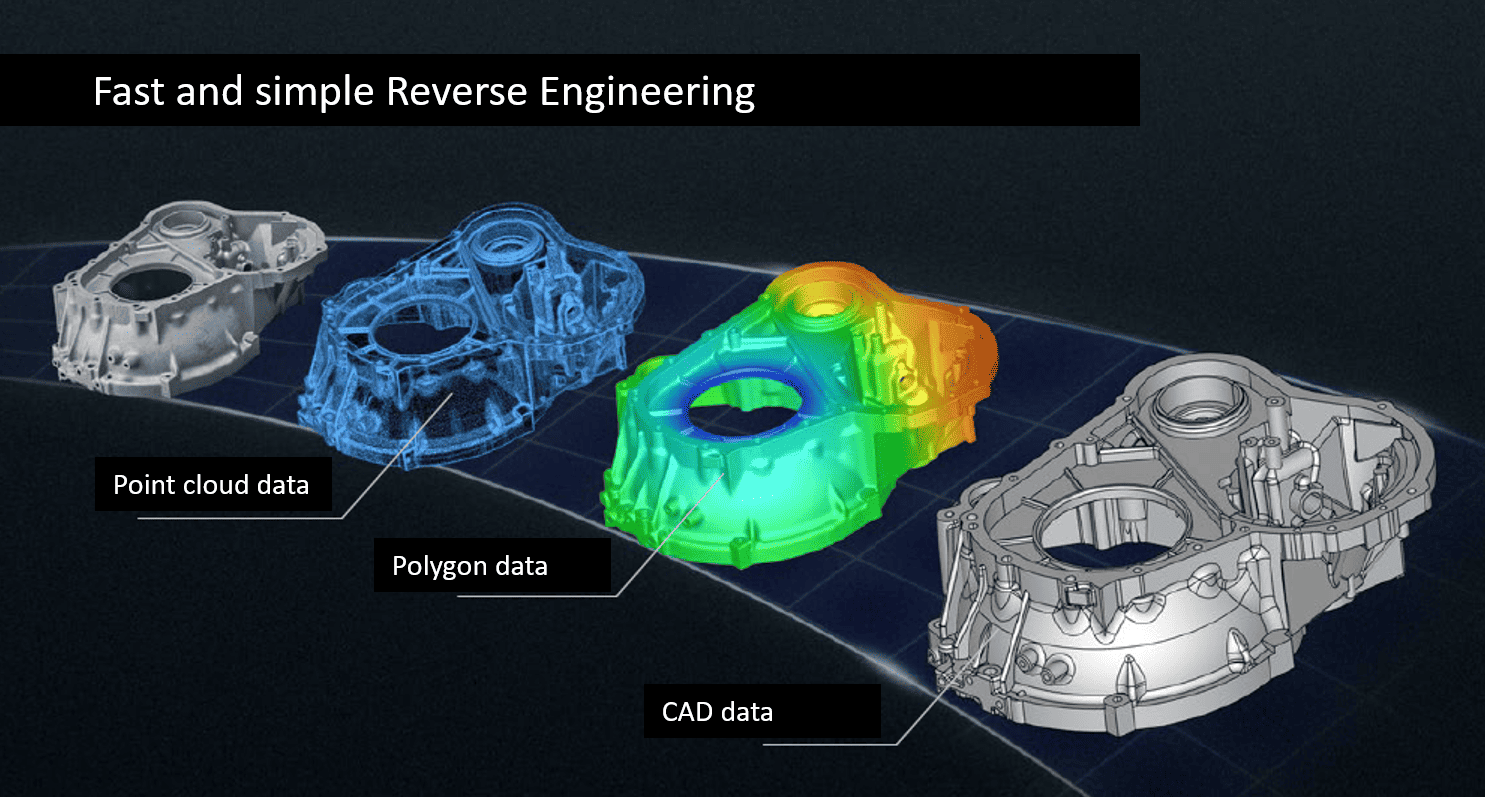

Reverse Engineering

In order to provide our customers with the best possible support, our engineering office is equipped with a 3D scanner, 3D printer, a high-resolution digital microscope and a material analysis device for plastics. The 3D scan provides us with the geometry and the material analysis tells us the material of the existing component, if this is not known.

For more info:

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.