Blow moulding is an efficient manufacturing process for the cost-effective production of hollow plastic parts. Compared to injection moulding, the tool costs for extrusion blow moulding and injection stretch blow moulding are significantly lower. In each individual case, it is important to consider whether blow moulding, injection moulding or rotational moulding is the most economical for your application. We will be pleased to advise you on this without obligation.

Specialist for industrial plastic tanks

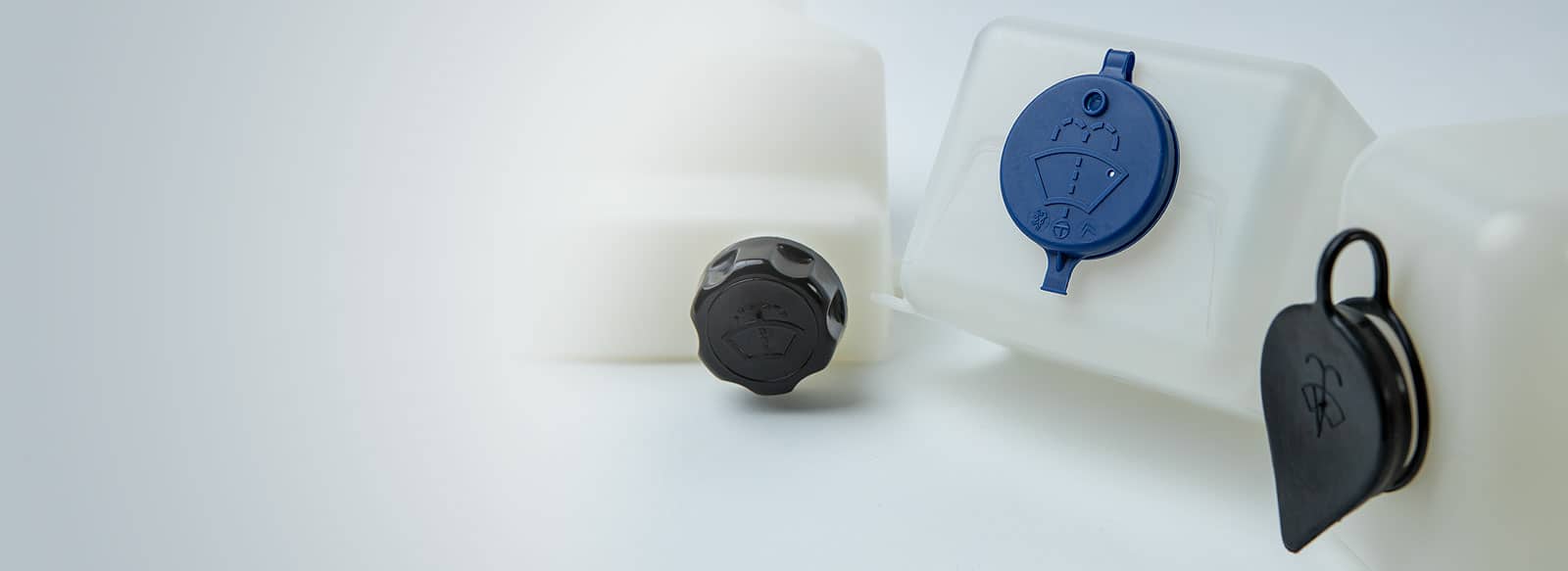

We have been developing and manufacturing plastic tanks for industrial applications for many years. These include wash water tanks for windscreen cleaning, Adblue tanks, expansion tanks or printer cartridges. For each component we check individually which manufacturing process is most economical. We usually provide this service without obligation and free of charge.

We want to offer you the technically and economically best solution and not the only solution we have in the drawer.

Development of plastic tanks and ready-to-install assemblies

As an independent development partner and series supplier, we are not limited to blow moulding as the only manufacturing process for plastic containers. Our expertise in Injection Moulding, Mirror Welding and Rotational Moulding enables us to find creative solutions. We always try to take a holistic view of our customers’ component or project. In concrete terms, this means that we do not necessarily have to develop a blow moulding solution because we have no other manufacturing options. If we think that another manufacturing process is more suitable, we will suggest it. There can be many reasons for this.

Criteria for selecting the appropriate manufacturing process

- Component geometry

- Inserts, openings, outlets

- Chemical resistance

- Operating pressure

- Wall thicknesses

- Temperature

- Quantity

- Component accuracy

- Surface quality

More than just blow moulding

- Inserting threaded bushes and inserts

- Component assembly

- Hot plate welding (mirror welding)

- Ultrasonic welding

- Machining post-processing

- Surface treatment

Process steps in blow moulding

Extrusion blow moulding is a coreless manufacturing process for the production of hollow plastic parts. In the first step the plastic is melted in an extrusion unit. A tubular, highly viscous preform is extruded from the melted plastic into an open mould. After closing the mould halves, compressed air is blown into the molten plastic tube (approx. 8-20 bar) so that it conforms to the inner contour of the mould. After cooling, the tool can be opened and the plastic part removed.

As a rule, the plastic parts must be reworked after blowing (e.g. drilling and deburring openings).

Materials

Whether chemical resistant, flame retardant or food safe, we can recommend a suitable material to suit your requirements.

- LDPE

- HDPE

- PE

- PC

- PP

- and many more

Fields of application for plastic containers

- Wash water tank

- Reserve tanks

- Bottles

- Compensation tanks

- Fuel tanks

- Canister

- Adblue tanks

- Water tanks

- and many more

Flexible tanks

There are applications where the tank shell must remain flexible so that the tank can fold or expand as required. For this purpose we have developed a system of flexible expansion tanks in which fabric-reinforced film composites are welded together. Optimised welding seams guarantee an operating pressure of up to 4.5 bar.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.