We develop and manufacture customer-specific injection moulded parts for all industries. Tailored to your needs, we work with you to find an economical solution and then implement it for large and small series. Short delivery times for initial samples and fast reaction times guarantee a scheduled start of production.

Competence in injection moulding

Injection moulding is a manufacturing process which is particularly suitable for the production of plastic parts in medium and high quantities. The main reason for this is the often very costly production of injection moulding tools. Nevertheless, we have found a solution to be able to produce even small to medium quantities economically – without loss of quality.

Expensive and complex injection moulding tools can be produced by many. However, to produce a plastic part economically even in small quantities is a challenge. Our credo “keep it simple” also applies to toolmaking.

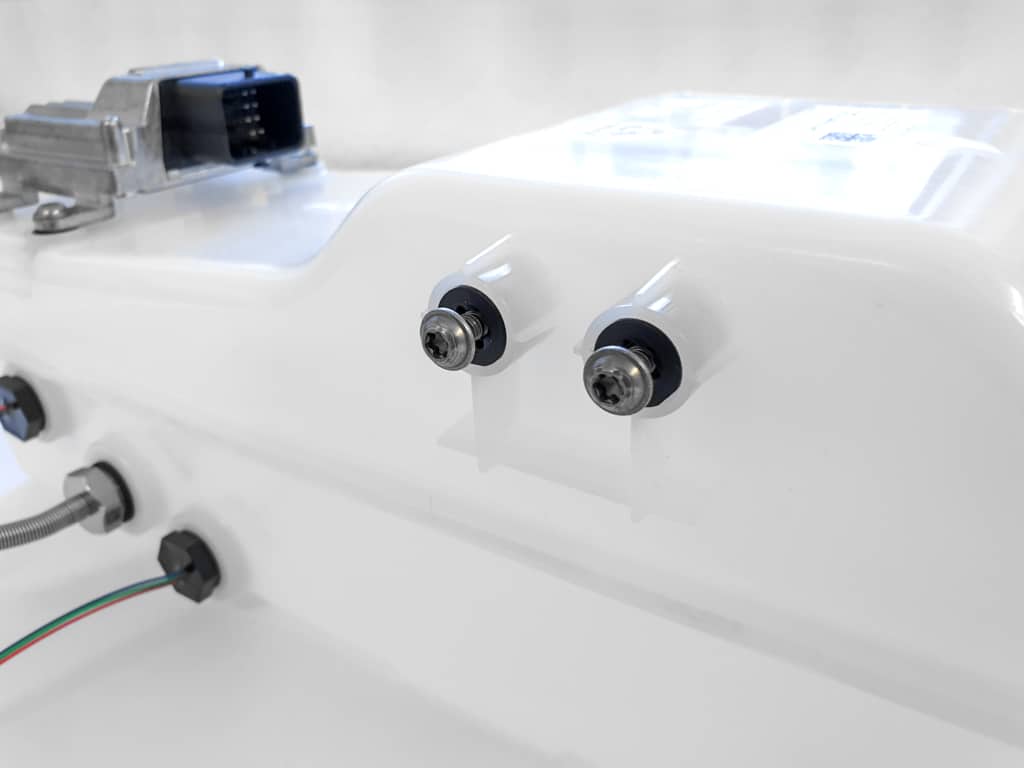

As an experienced supplier for plastics technology in the automotive sector, we know what it means when a series is started and no bottlenecks are allowed to occur. The processing of thermoplastics into complex components is a challenge that we face with enthusiasm every day.

Materials

Depending on your needs and requirements, we can recommend a material for the economic implementation of your product. Additives (e.g. pigments, flame retardants, glass fibres etc.) can be used to tailor the materials even better to the application. Below you can see a selection of frequently used plastics.

- PE

- HDPE

- PP

- PMMA

- ABS

- PC

- PA

- PVC

- and many more

More than just injection moulding

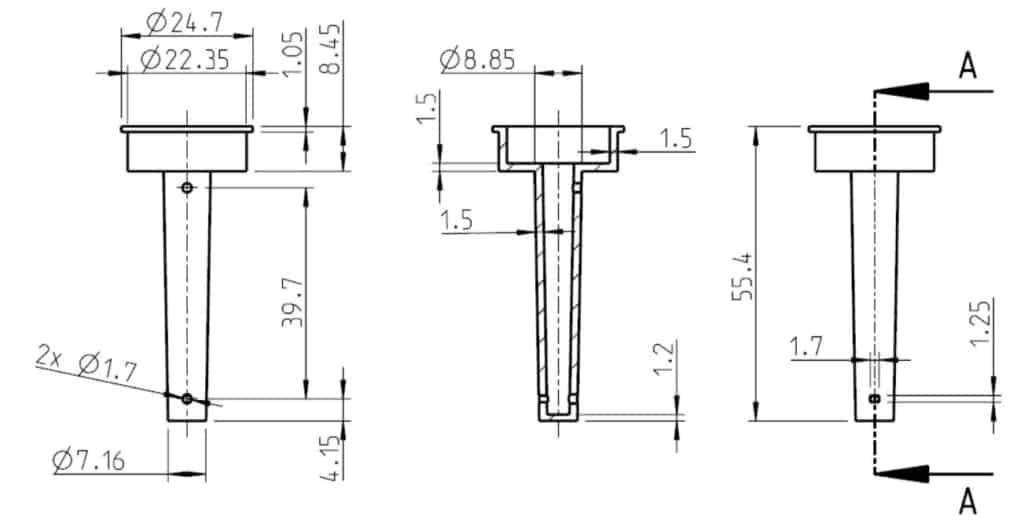

- Inserting threaded bushes and inserts

- Component assembly

- Hot plate welding (mirror welding)

- Ultrasonic welding

- machining post-processing

- Surface treatment

Your specialist for plastic tanks and containers

As an experienced supplier for the automotive industry we have specialized in the production of plastic containers and tanks. For plastic tanks, which cannot be produced with Blow Moulding due to their geometry, half-shells have to be injection moulded and then welded into tanks. The only alternative is rotational moulding, which, however, reaches its limits with higher quantities.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.