There are almost no end products in which plastic parts are not used somewhere. The reasons for this are obvious: there are soft, elastic plastics (elastomers) but also very hard and tough plastics (thermoplastics and thermosets). The possibility of optimising materials perfectly for an application area has paved the way for plastics technology in recent decades.

Overview of our possibilities

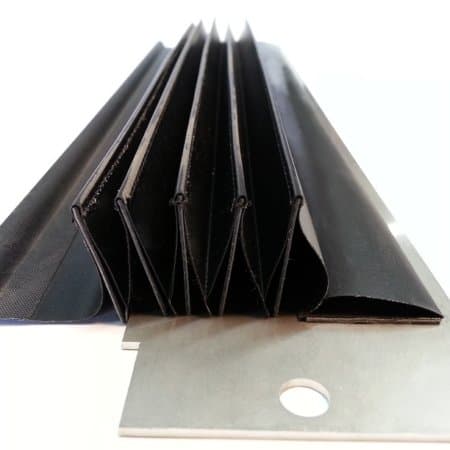

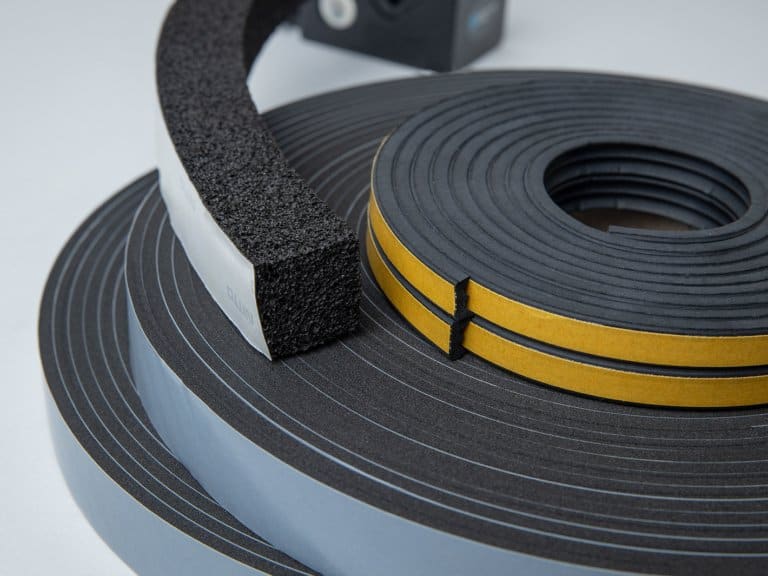

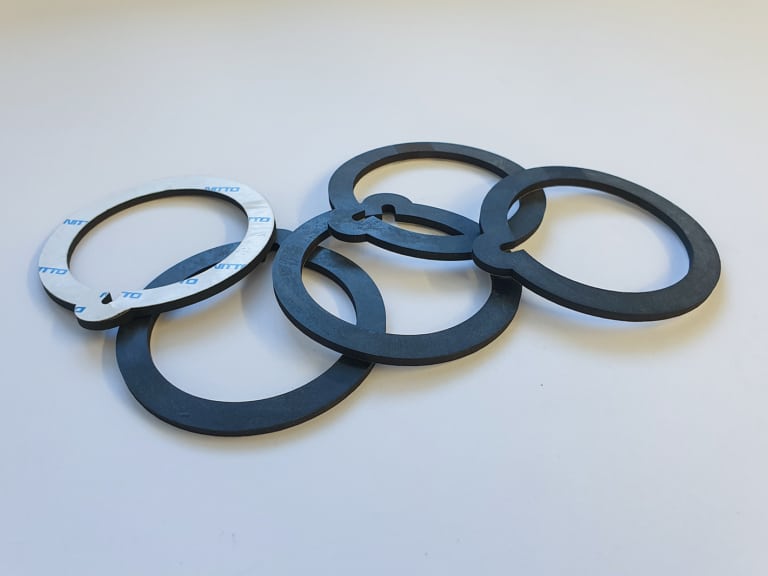

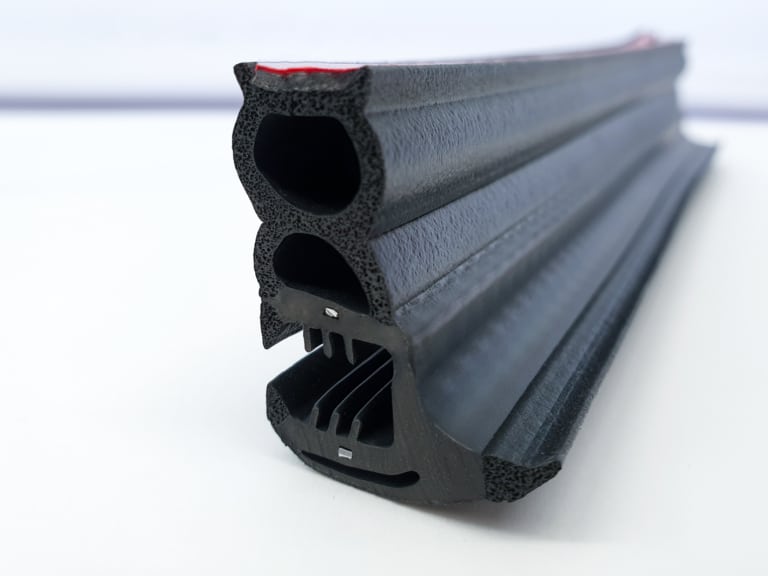

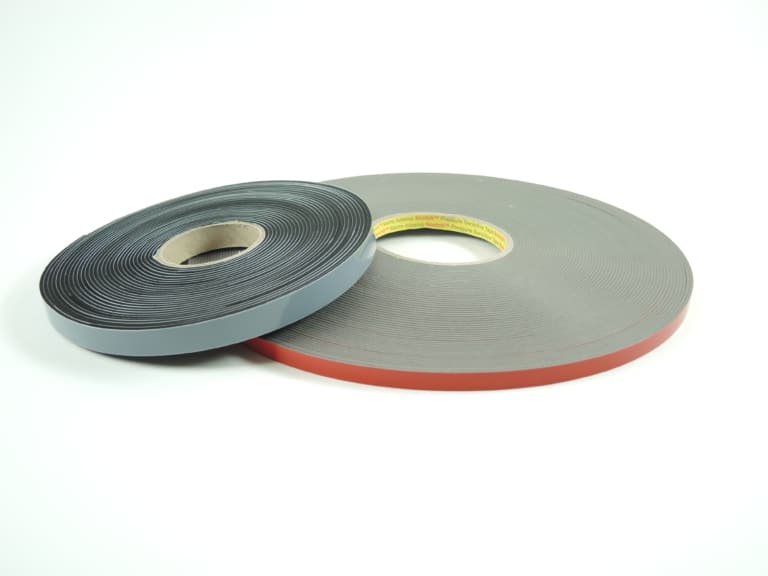

Specialised in seals, profiles and moulded rubber parts

For historical reasons, we have specialized in the development and production of elastic components, e.g. Seals and Profiles, Moulded Rubber Parts and Hoses. The broad application in the automotive industry offered numerous opportunities to expand our know-how in more than 20 years. As a result, we have been able to develop further and constantly expand our range of services, so that today we are in a position to supply our customers not only with individual parts, but also with Complete Assemblies. We support our customers right from the development stage.

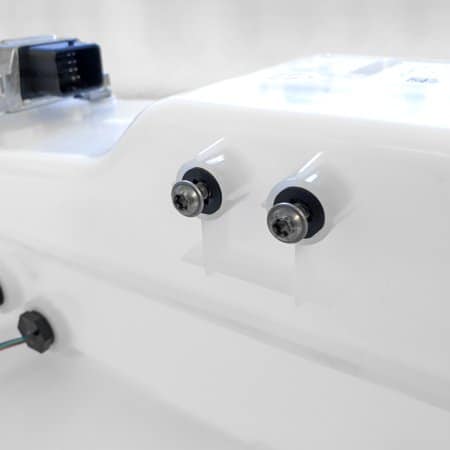

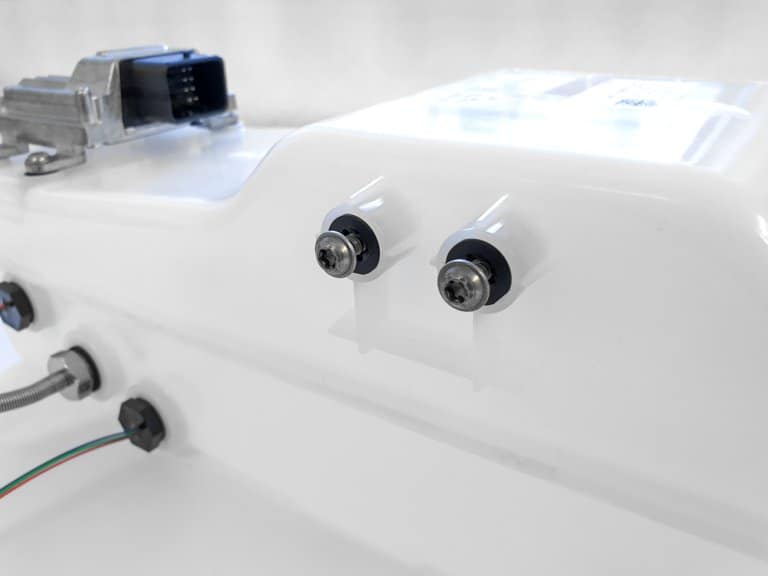

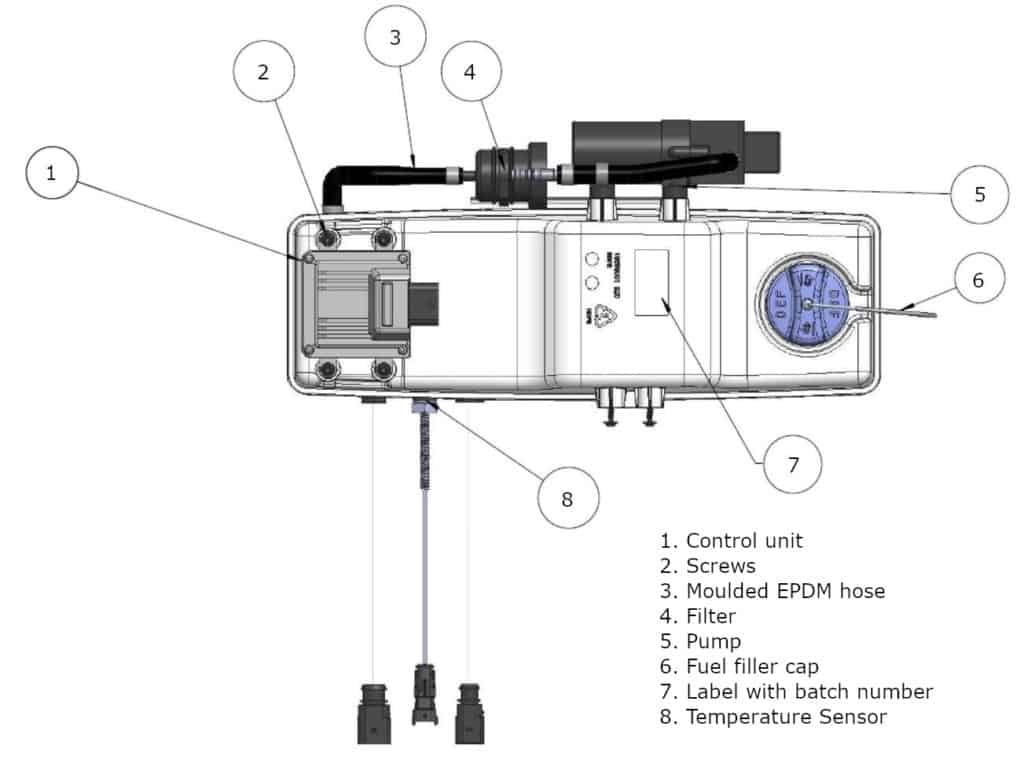

Specialized in plastic tanks

Besides rubber parts and seals of all kinds, we have specialized in the development and production of Plastic Tanks. This combination is obvious, if you consider that many tanks are equipped with sensors and pumps, which in turn are connected to a cable set. The challenge in tank construction is, among other things, the sealing of the interfaces. Special seals (Rubber Parts) are often required for this.

We can develop and manufacture both rigid plastic containers (e.g. made of HDPE and PP) and flexible containers (inflatable) made of films and composite materials (e.g. made of TPU, PVC, PE). All containers can be optimised with regard to media resistance and maximum operating pressure.

Materials for seals and rubber parts:

EPDM, CR, NR, NBR, HNBR, Silicone, TPE, FPM/FKM (Viton), PVC etc.

Materials for plastic tanks:

HDPE, PP, PE, PA, ABS, PVC, TPU etc.

Plastics technology: Development of individual parts and assemblies

If required, we support our customers right from the development stage. Starting with the choice of material, up to the construction, we can display everything in CAD and also simulate many things. As an independent development partner and series supplier, we strive to find the best technical solution that is also economically viable. Therefore we pay attention to a production-optimized component geometry already in the development phase.

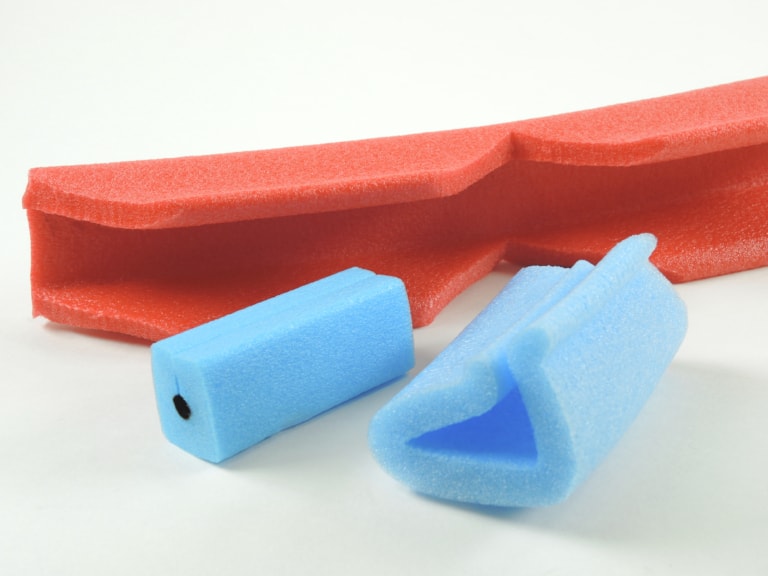

Development supported by 3D printer

With our own 3D printer, we can print prototypes and fixtures in the shortest possible time in order to carry out initial functional tests. We have the possibility to process both solid and semi-elastic materials.

Use our all-round service

- Personal customer advice and support

- New development, further development, cost optimization

- Creation of concept drawings, production drawings and material lists (BOM)

- Fast prototyping

- Creation of initial sample inspection reports (ISR)

- Demand-oriented production

- International serial supply

- Computer-aided process documentation

- Batch Traceability

- Continuous quality monitoring

Any more questions?

We are happy to advise you and provide you with a non-binding offer.